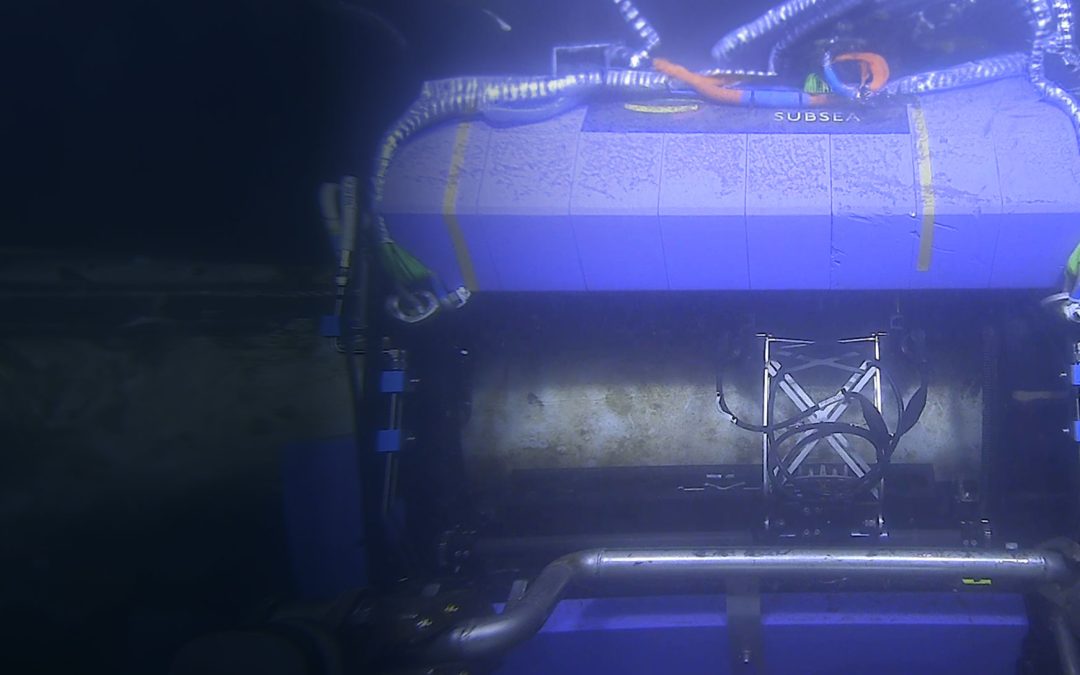

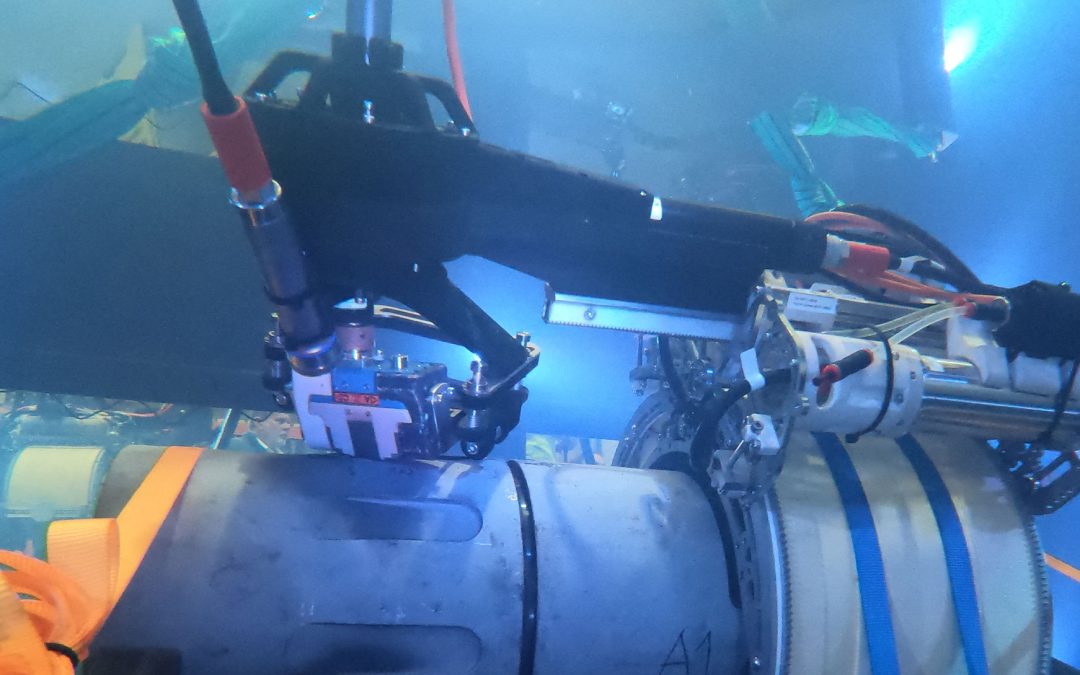

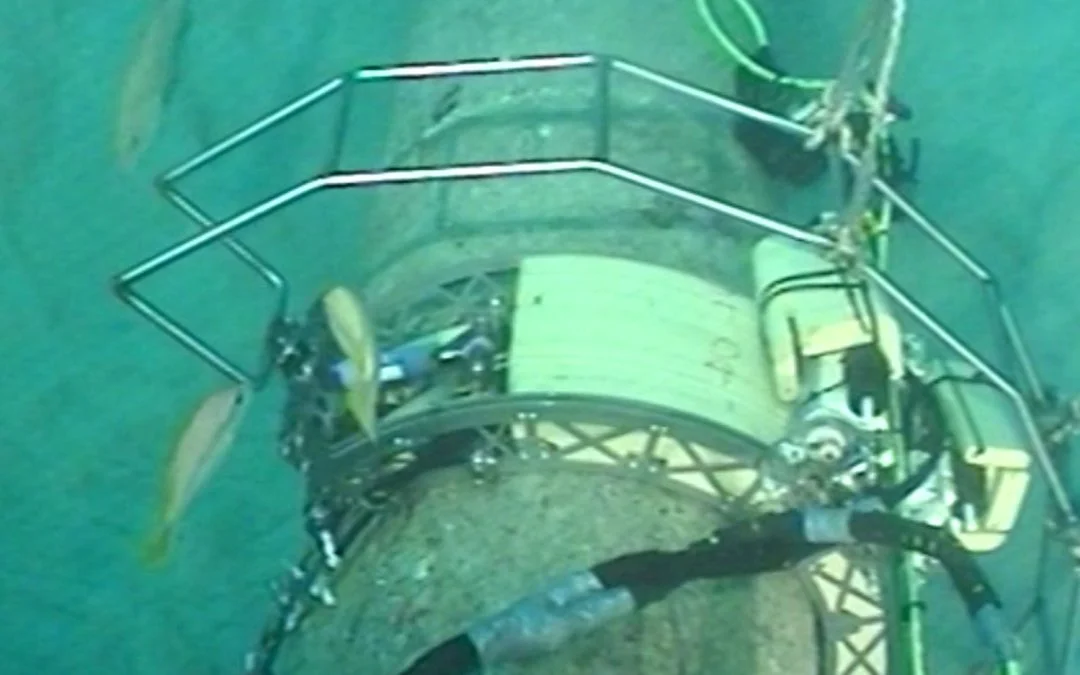

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...