The Challenge

Beach Energy Ltd contracted TSC Subsea to carry out a wall thickness inspection through coating on the 20” Otway pipeline located near the Thylacine A platform in the Bass Strait, Australia. The inspection was to determine the size and depth of corrosion which had been identified during a previous In-Line Inspection (ILI).

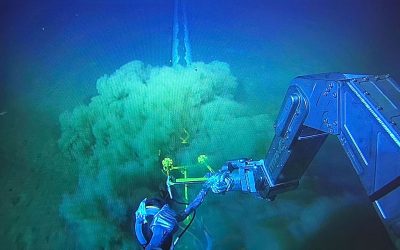

Pipe field joints were located at a depth of 100m above rock and coral, so a diverless inspection by ROV was required. The difficult-to-penetrate anti-corrosion Canusa wrap coating on the field joint, ruled out conventional ultrasonic inspection so the inspection would have to be carried out by Acoustic Resonance Technology (ART). However, the field joint was too narrow for TSC Subsea’s standard ARTEMIS® to fit accurately into the joint. A solution to the problem had to be developed.

The Solution

TSC Subsea responded by developing a new ROV deployed automated scanning tool, the ARTEMIS® vCompact, within a turnaround time of just six weeks. The ARTEMIS® vCompact is a smaller, lightweight version of ARTEMIS®, which deploys the same ART technology but on a much smaller, more flexible frame. The new system fit perfectly in the field joint area, enabling precise semi-automated scanning in both the axial and circumferential directions, providing high resolution wall thickness measurements and overcoming the problem of carrying out a tight access pipeline field joint inspection in between concrete weight-coats and piggy-back line.

The high penetration capability of ART also overcame the problem of the difficult-to-inspect anti-corrosion wrap, fully penetrating through the coating to accurately inspect the field joint.

The Results

The inspections were successfully carried out and completed within two days with minimal excavation required. This confirmed that the ARTEMIS® vCompact, deploying ART technology, was capable of carrying out inspections to the highest standard in difficult, tight access areas.

All data from the remote inspection was analysed remotely by a team based in the Norway, saving costs and minimising POB.

The development of the ARTEMIS® vCompact has opened up new opportunities for applications where size is critical due to tight access. There is particular potential for inspections in and around subsea structures where accurate remaining wall thickness measurements are critical for safe operations.

Having successfully completed its first trial, Stephan Freychet, Senior Project Manager, said the project demonstrated the future potential of ARTEMIS® vCompact and the capability of ART. “The new ARTEMIS® vCompact can be deployed in a number of applications where size is critical due to tight access,” he said.

“We now see huge potential for its use in and around subsea structures where accurate remaining wall thickness measurements are critical for safe operations.’’

“This job presented a combination of fairly unique challenges, but the skill and expertise of our development team and the speed with which they reacted to adapt existing technology to meet the brief, has resulted in a new tool which now has scope for much wider application right across the subsea sector.”