The Challenge

TSC Subsea was contracted by a client to carry out wall thickness assessment of Condensate Export Pipeline (CEP) and Pipeline End Manifold (PLEM) without removing the protective concrete weight coat (CWC). The assessment was required as the client was concerned that the integrity of the steel pipework under the concrete had been compromised.

CWC is typically a carbon steel pipe with a concrete coating that provides strong downward force protection and acts as negative buoyancy for the pipeline.

Although the concrete provides a suitable protective layer it can act as a barrier to most external non-destructive testing (NDT) methods. Concrete has a coarse grain structure, often forming a 2- to 4-inch thick coating which rules out all ultrasonic methods of testing and is restrictive to most electromagnetic inspection technologies.

The scope was particularly challenging as the operators had to collect automated data using TSC Subsea’s vCompact scanner system as well as communicate with, and navigate, a diving crew to scan areas such as the elbows on the PLEM that were not accessible to the robot. The combined diver applied and robotic collection required careful planning and communication. Due to the client’s critical timings and short inspection window, it was challenging to ensure all inspection locations were completed within the timescale.

The Solution

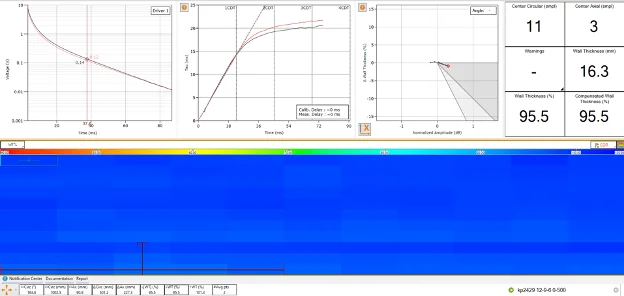

Our latest NDT technology, SPECTA (Subsea Pulsed Eddy Current Testing Array), was our first choice for this project. Pulsed Eddy Current (PEC) is one of many TSC Subsea NDT technologies for carrying out corrosion mapping of cylindrical components. PEC is the most powerful inspection technique in terms of through-coating wall thickness measurement capability. It is a semi-quantitative screening method and, although it does not provide the accuracy of ultrasonics, can give reliable readings for the remaining wall and corrosion depth.

A benefit of PEC is that areas can be scanned in ‘screening mode’ with larger grid sizes to identify any potential defect areas. The areas identified can then be re-visited and scanned at a higher resolution for more accurate results.

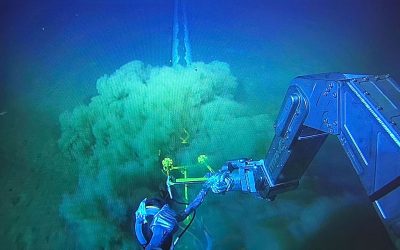

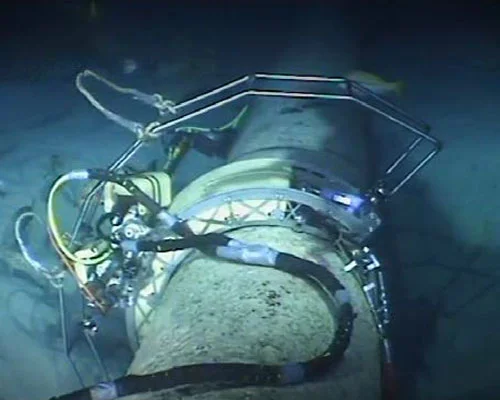

To deploy the SPECTA probe, the vCompact X-Y robotic scanner was selected for this inspection. This ROV deployed delivery system was modified for this particular application as an alternative clamping mechanism to the standard permanent magnets was required to attach the scanner to the inspection surface, due to the lack of magnetic adhesion created by the concrete coating. Instead, hydraulic clamps were attached to the robot to allow it to attach to the concrete pipe and create an anchor for the articulating arm to collect the PEC readings. During the inspection, the vCompact covered 180 degrees of the pipe with one placement and completed a 600mm axial scan in less than an hour.

The project was also supported remotely from the UK to help expedite analysis and provide instantaneous results of any areas of concern.

The benefits of using the combination of SPECTA along with the vCompact tooling solution are pinpoint accuracy of location scanning and accuracy of plotting any defect locations (particularly over diver deployed offerings). Fully encoded scanning also allows for repeatable inspections, which can add to future monitoring or fitness for service assessments.

The Result

The project was delivered on time and within budget. Successful data was obtained, and no areas of concern were identified. The SPECTA vCompact solution was deemed a success, and diver deployed inspection was kept to a minimum reducing risk to the divers.

SPECTA is the first commercially available solution for subsea pulsed eddy current array inspection. As the majority of NDT technologies cannot be used with concrete, without the TSC Subsea technology, the client would have had to remove the concrete coating to carry out the assessment, which would have resulted in high costs and significant operational impacts for the client. It is the perfect tool for all corrosion mapping and in-line inspection (ILI) follow-up, and can be fitted with other NDT sensors to complement the PEC data.

Comment

CWC pipework is extremely common, and many operators have to inspect the integrity of their pipework in similar conditions. A combination of detailed risk-based integrity assessments and often the data provided from In-line Inspection (ILI) requires operators to assess the remaining wall thickness of their subsea assets.

TSC Subsea is not limited to a single NDT modality and we can select what is most appropriate for a client’s needs.