MagCrawler™

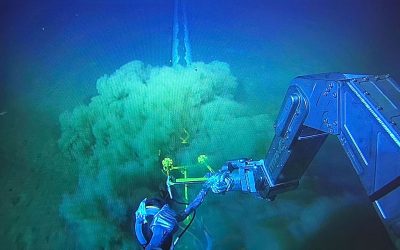

Subsea and splash zone robotic crawler

The TSC Subsea MagCrawler represents the latest in remote subsea inspection technology. It was developed specifically to enable the ROV deployment of TSC Subsea’s exclusive Alternating Current Field Measurement (ACFM®) Array Probes to inspect subsea geometries such as circumferential welds in pipes/tubulars, fillet and full-penetration welds in plates.

MagCrawler™

The MagCrawler™ offers smart deployment and operation:

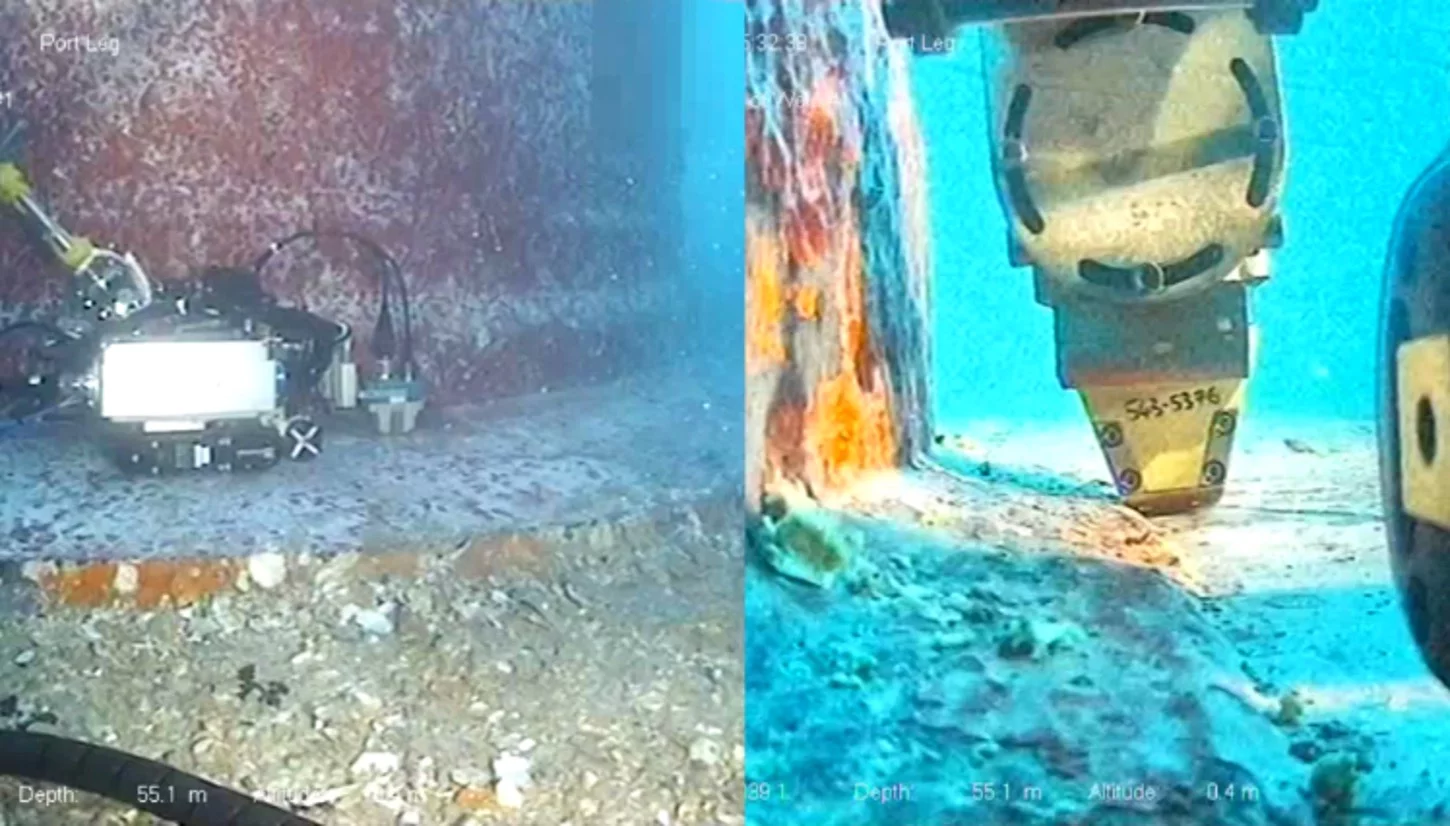

- Once the MagCrawler™ magnetically attaches to the inspection surface, the ROV releases it.

- Two rubber caterpillar tracks provide crawler traction and are easily manoeuvrable to steer the crawler over the inspection surface.

- Motorised mechanisms allow the probe to be deployed accurately over the weld to be inspected.

- A 360° rotational head allows flange welds to be inspected with full coverage of the weld and the heat-affected zone.

- Passive compliance holds the probe in contact with the inspection surface, ensuring the probe is aligned correctly with the inspection surface during operation.

- Dedicated control software follows simple weld paths.

- Positional adjustments can be made in both longitudinal and transverse directions, which allows full coverage of the area to be inspected.

- The MagCrawler™ captures high-quality Non-Destructive Testing (NDT) data with fine motor controls, and on-board, backlit cameras provide real-time visual feedback to verify that the stipulated scan criteria are being met.

The MagCrawler:

- Can easily maneuver on diameters greater than 760mm (30 ins)

- Uses a closed-loop feedback motor control for accurate weld tracking and a uniform scan speed

- Can inspect through paint and other coatings

- Is tolerant of residual marine growth

NDT Technology Options

Videos

Get in touch

Downloads

Case Studies

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Rapid Hydrate Plug Detection Solution for Subsea Pipelines.

Introduction In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for...

Smooth Sailing with ACFM Crack Assessment on Cargo Ship Propellers.

The Archon Gabriel Bulk Carrier was navigating the cold waters of the Gulf of Finland. The harsh sea conditions, laden with sea ice, posed significant navigational challenges and resulted in the ship’s 6-meter diameter bronze propeller suffering ice damage. Given the...

Diverless ACFM Inspection Solution for FPSO Bilge Keel Weld Integrity Assessment.

FPSO operators are increasingly seeking ways to inspect their hulls below the waterline without resorting to drydocking, a costly process that entails significant production loss, rendering it inefficient and logistically challenging. Recognising the benefits of a...

Our Services

Subsea Structures

Splash Zone

Vessels and FPSOs

Flexible Risers

Pipelines

Grouting

Solutions