DexScanner™

Subsea Weld Inspection of Complex Geometries

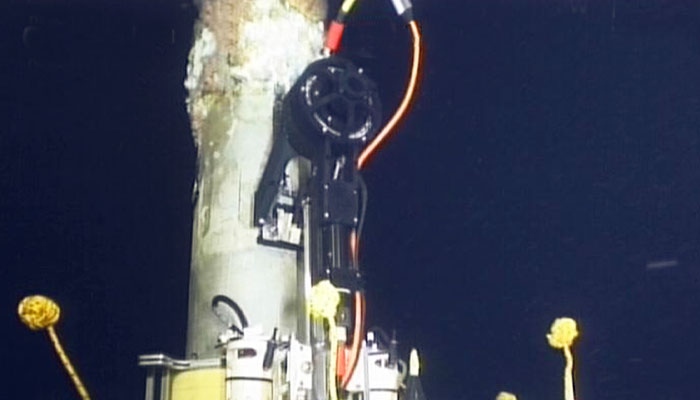

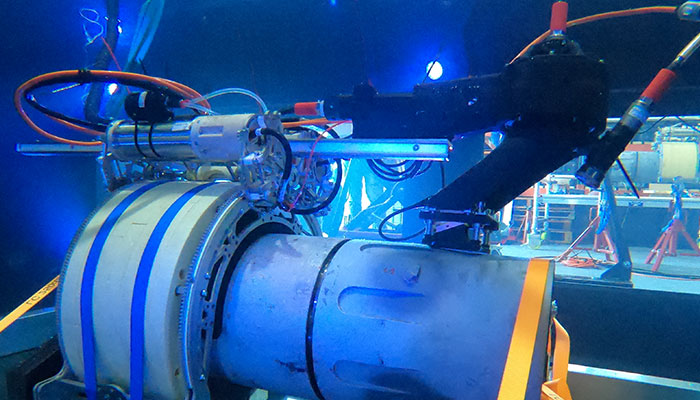

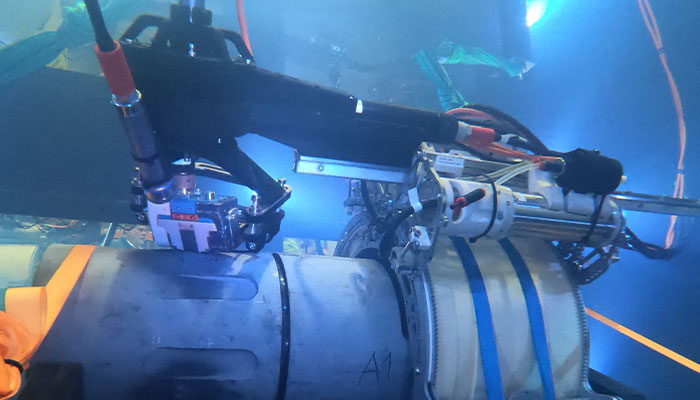

The DexScanner subsea weld inspection robotic scanner represents an enhancement of the existing NodeScanner™, boasting an extra 360-degree scanning axis. This additional feature provides it with a level of dexterity similar to that of a human hand, enabling precise scanning movements across semi-elliptical weld surfaces.

By harnessing the power of Subsea Phased Array (SPA™) and Alternating Current Field Measurement (ACFM®), DexScanner exhibits the capability to detect and accurately size surface and subsurface cracks in intricate welds.

With a growing emphasis on the adoption of diverless robotic solutions to enhance safety in subsea operations, the inspection of intricate subsea welds has become a greater challenge. The capacity to carry out these weld inspections with unwavering confidence holds substantial importance within subsea asset lifetime extension initiatives.

DexScanner, through its unique capability to seamlessly integrate dual NDT methods, ensures comprehensive coverage while simultaneously offering cost-saving advantages to our clients by consolidating their inspection needs under a single service provider.

Subsea Phased Array Mode

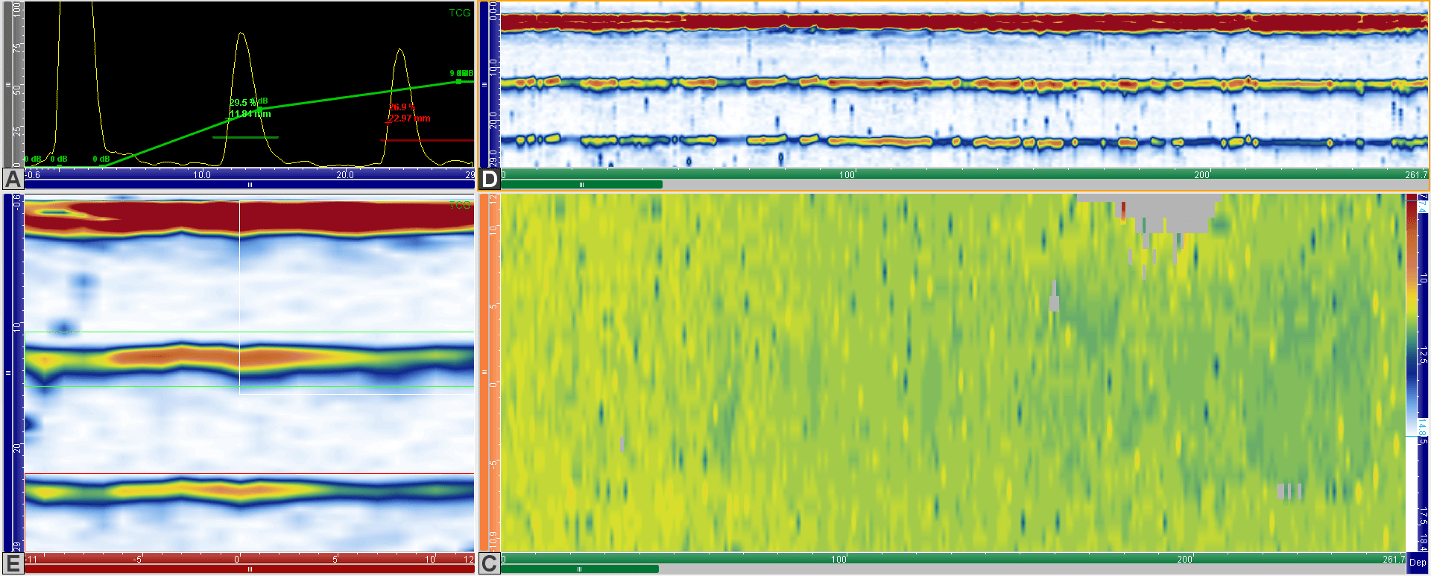

Subsea Phased Array (SPA™) technology has the ability to create a volumetric beam that can interrogate the whole weld volume without the need to raster scan. The beam can be generated to include a number of inspection angles, and operators can set the technique to specifically inspect any given weld. The advanced software within the SPA system provides 3-dimensional images and part specific overlays that will improve the probability of detection and help produce a report that can easily describe the condition of the weld.

ACFM Mode

ACFM is a electromagnetic inspection technology has been the method of choice for detecting and sizing subsea surface-breaking cracks in critical welds. Recognised and approved by many certification bodies, including DNV, ABS and Lloyds, the technique has been used successfully to supersede traditional non-computerized and more user-dependent methods, such as magnetic particle inspection (MPI).

NDT Technology Options

Data-Rich Inspection Information

Subsea Phased Array

The SPA system is designed to offer the very best inspection solution for detecting wall thickness reductions due to corrosion, abrasion and erosion. The system’s high resolution is achieved by utilising an effective ultrasonic beam that is 60mm wide and can collect A-Scan information every 0.5mm. This ensures 100% coverage of the inspection area.

Case Studies

Deploying dual NDT Methods for the Inspection of Complex Welds

The Challenge TSC Subsea received a request from a major operator, Equinor AS, to evaluate the feasibility of inspecting subsea risers coated with thermally sprayed aluminium (TSA).

Subsea Phased Array (SPA) for Duplex Bends

TSC Subsea were challenged to investigate sand erosion concerns on subsea structure piping off the coast of Western Australia. The inspection campaign covered multiple assets, including Pipeline End Manifold (PLEM), tie-in spool and subsea cooling skid.

Custom Designed Extrados Scanner for Inspection of Subsea Gas Lift Riser

TSC Subsea rises to the challenge of scanning and data collection on small diameter pipe bends by developing a custom designed “extrados scanner” for inspection of gas lift risers.

See all case studies

Videos

Get in touch

Downloads

Our Services

Subsea Structures

Splash Zone

Vessels and FPSOs

Flexible Risers

Pipelines

Grouting

Solutions