The Challenge

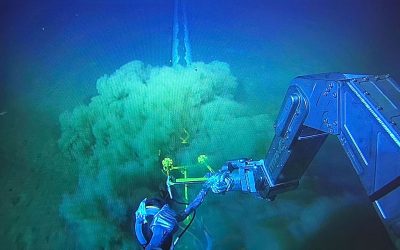

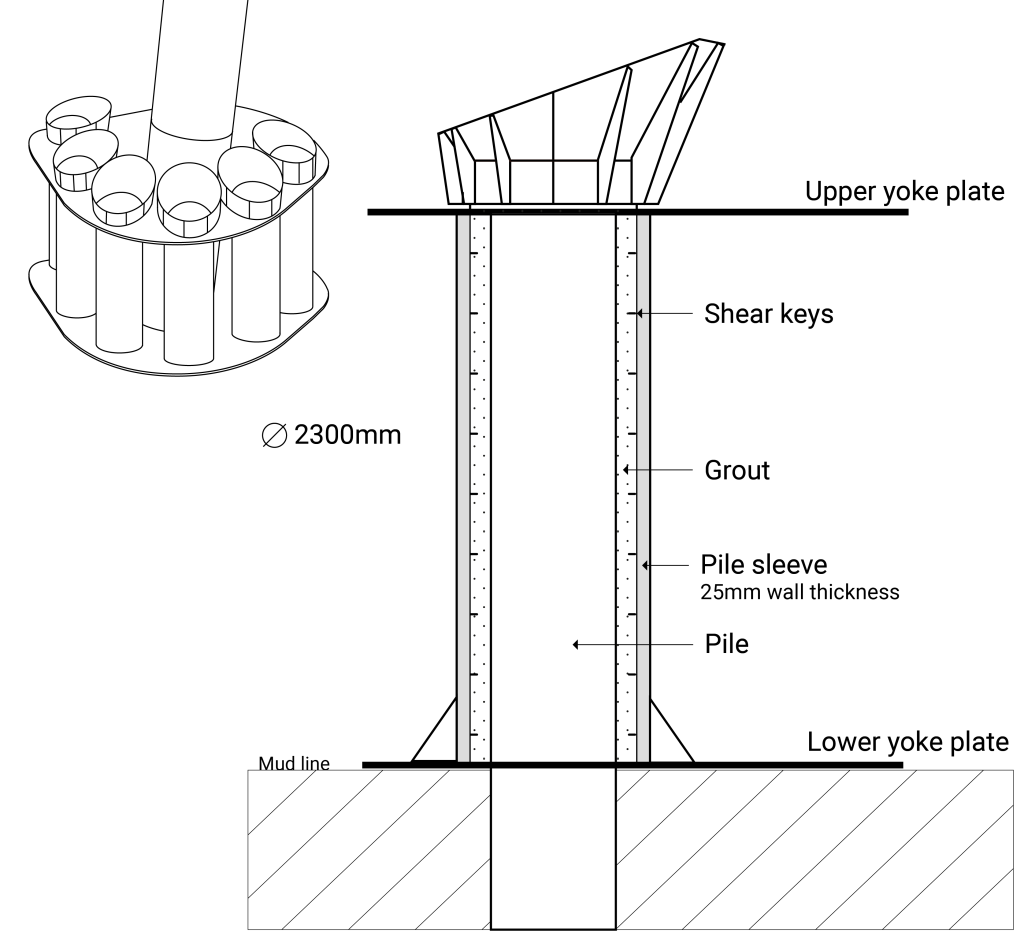

A North Sea operator who wanted to confirm the presence and integrity of grouting on four lower pile sleeves with a diameter ranging from 2300 to 2762mm and a wall thickness of 25mm of a subsea structure identified that there was an industry technology gap and that there was no currently available system that could carry out this type of inspection.

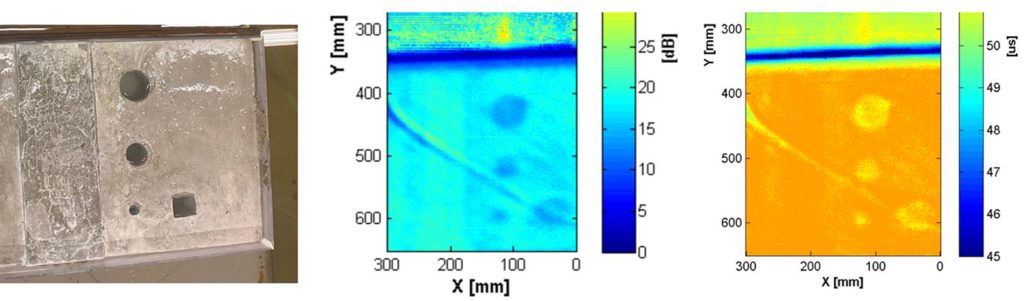

Such inspections aim to verify the grouting integrity behind the pile sleeve and look for features and inconsistencies, such as voids, crushing and cracks in the grout, behind the pile sleeve and dis-bonding between the pile sleeve and grout, which may have developed over time in subsea grouting connections.

The Solution

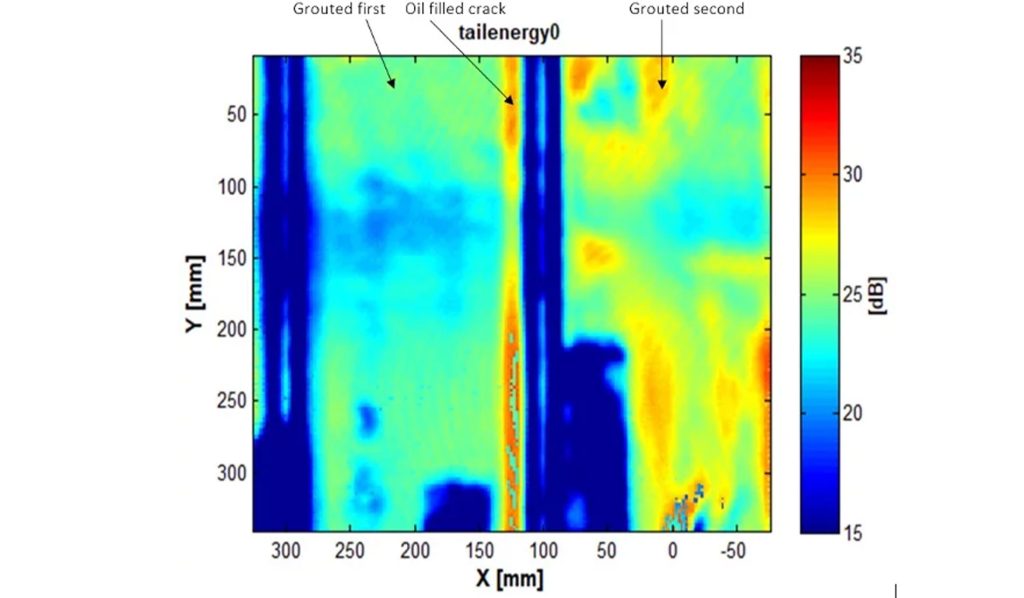

TSC Subsea deployed its Acoustic Resonance Technology (ART) for this project. ART is a frequency-based acoustic inspection method specifically suited for detecting the various failure modes found both in the steel and the grouted structure in the annulus.

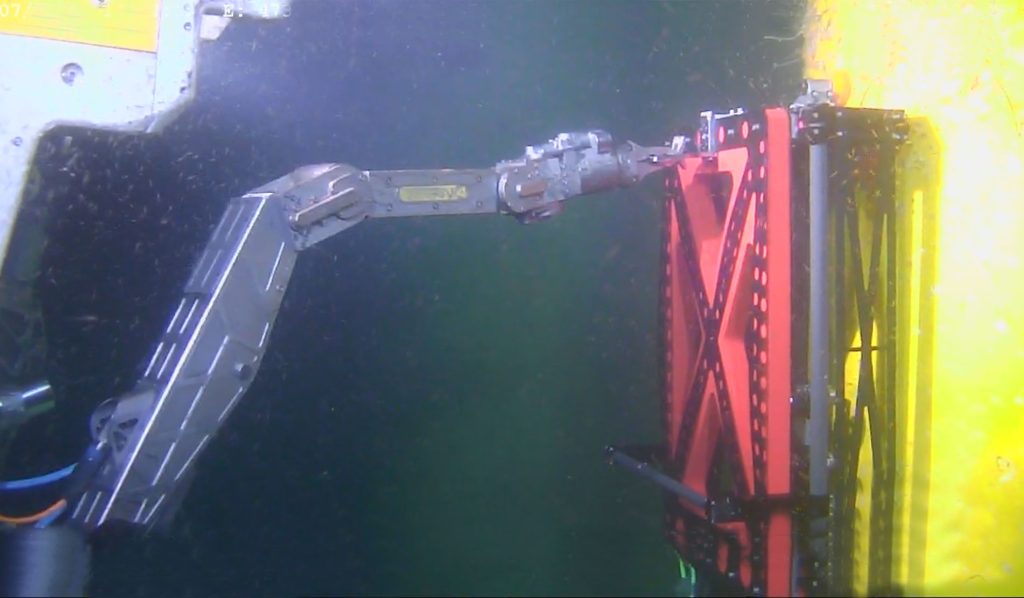

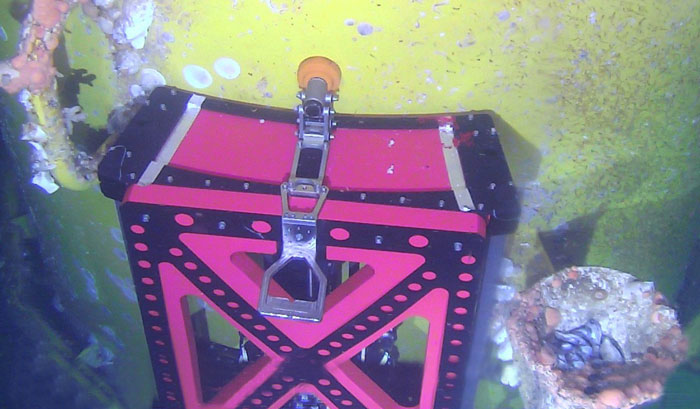

For this campaign, TSC Subsea specifically developed the ART GUIDE, an acoustic scanner which is magnetically attached to the structure by a work class ROV (WROV).

The new ART GUIDE solves a challenging and unique application with no alternative solution available to the market. The system underwent a rigid testing and verification programme to prove its ability to detect the failure modes most relevant for grouted connections.

The ART Guide system is designed with specific attachments that can be interchanged to facilitate the inspection of various pile sleeve diameters.

Using multiple sensors, it can scan a 0.5m x 0.5m window in 20 minutes, typically taking a shift to inspect an Ø3m diameter leg.

The benefit of this solution is that it is capable of verifying the grouting integrity from the outer surface at the jacket’s low points. This is the area that is most exposed to the type of loads affecting offshore structures.

It is an area which previously has not been accessible for inspection due to inspection technology limitations.

While cleaning to remove hard marine growth is required by industry standard tools before an inspection, the technology is not affected by soft marine growth and can scan through thick layers of painted surfaces.

Project Highlights

- Industry’s first grout integrity inspection with ART

- High speed scanning at 0.5 x 0.5m2 in 20 minutes

- Scan through soft marine growth and painted surfaces

- Calibrated against failure modes relevant to grouted connections

- Parallel inspection of wall thickness measurements

Other ART GUIDE Applications

- Any grouted connection inside pile sleeves on offshore jacket structures

- Offshore wind turbines with grout connection

- Underwater Inspection in Lieu of Dry-Docking (UWILD) of Ship hulls

- Floating production storage and offloading (FPSO) vessels

The Result

The project was a success and completed on time and within budget. Had this TSC Subsea technology not been available, the consequence of doing nothing would have raised concerns regarding the integrity of some offshore structures. Understanding grout integrity allows clients to make informed decisions as to whether remedial action is required.

The operation requires the ART GUIDE scanner to be magnetically attached to the pile sleeve surface, allowing the scanning operation to be conducted uninterrupted.

A combination of effective buoyancy and magnetic force allows the WROV to easily deploy and reposition the ART GUIDE in cases where multiple scans are required.

Several successful projects have been completed, with significant interest now coming from the offshore wind sector, where the same grout connection design and subsequent failure mechanisms apply.

ART GUIDE sample data

Client feedback was extremely positive, particularly regarding uptime and professional integration.

TSC Subsea Project Manager