The Challenge

Flooded annulus due to an external sheath breach has proven to be one of the top failure modes of flexible riser systems. It has also been found that CO2 permeation from produced fluids can accelerate armor wire corrosion, leading to flexible riser failure.

By detecting possible presence of liquid within the annulus, the likelihood of integrity threats to the riser system in operation can be monitored, giving early input to a long-term strategy for risk mitigation.

There are various ways to test for flexible riser flooding detection. However, insulated production flexibles pose the biggest challenge and have long been uninspectable by external scanning methods due to the thick multiple insulation layers used by flexible pipe manufacturers. To add to the complexity, some designs allow for wet insulation by implementing water barriers into the layer structure. The active annulus, containing the metal structure, is however designed dry.

The large variety of layers and materials used in the production of flexible pipe adds to the complexity of the inspection process. A significant variation of insulation materials and thicknesses is currently applied to accommodate operational conditions and to adapt to environmental challenges.

The Solution

TSC Subsea has used ART to develop a methodology for the detection of liquids in the annulus of production risers and gas injection risers. Using software and hardware, developed in-house by TSC engineers, annulus state was proven on samples provided by an independent third party.

The robustness of the software was benchmarked against known condition from ambient pressure to several thousand metres of water depth, achieving proven results through blind testing under pressurised conditions.

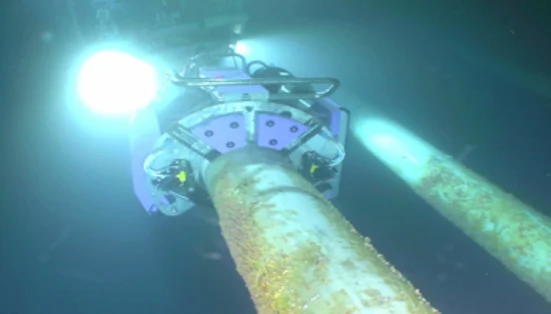

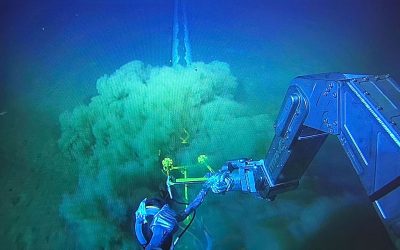

ARTEMIS® with its universal “smart” design and its deep-water track record is used to deploy ART. Dynamic risers and flowlines can both be inspected during one deployment, saving significant time during a vessel campaign. ARTEMIS® can be supplied as a fixed installation to an ROV or as a wet mated, manipulator handled solution.

The Benefits

Field operations have been proven over a large number of deployments on flexible risers at depths from 100m to 2250m. The track record includes both gas injection and flexible insulated production risers provided by several flexible pipe manufacturers.

Although the combined thickness of the insulation layers typically vary according to the design, ART methodology has been proven on annulus space of several inches, containing multiple layers of insulations made of a range of materials.

By using ROV scanning tools and flexible pipe annulus diagnostics, annulus state can be verified at an early stage. This reduces the chance of catastrophic failure, allows for careful planning of longer-term mitigation activities, and can lead to significant cost savings through the avoidance of lost production due to unplanned change-out.