vCompact

High-resolution wall thickness measurement of subsea pipelines

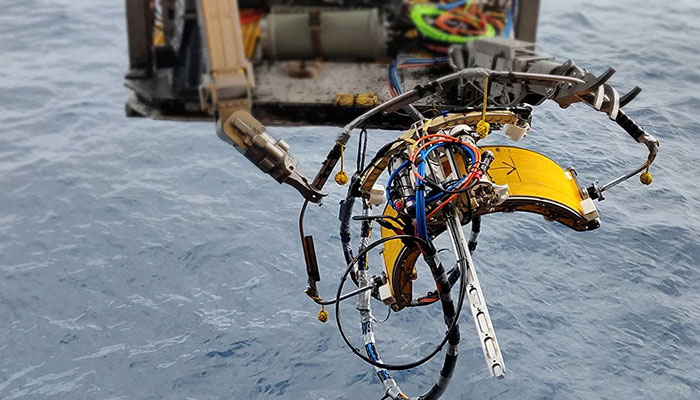

TSC Subsea’s engineers designed and developed the vCompact specifically for seamless integration with inspection and work Class ROVs, enabling the remote inspection of subsea pipelines and structures. Equipped with a range of Non-Destructive Testing (NDT) technologies, such as Acoustic Resonance Technology (ART) and Subsea Pulsed Eddy Current Testing Array (SPECTA™), the vCompact excels in high-resolution wall thickness measurements even through thick subsea attenuative materials and concrete weighed coats (CWC) .

vCompact

The vCompact is the ideal solution for tight access field joint, right access tubular, subsea jumpers, risers and riser guides and hot tapping locations inspection without the need for coating removal. Acoustic Resonance Technology (ART) has been built into the tool design to make high accuracy wall thickness measurements and corrosion mapping possible through penetrating and inspecting subsea coating with lightweight, high-precision two-axis scanning.

Strong magnetic feet or hydraulic clamps enable the scanner to be securely fixed in position, and once delivered, the ROV will detach, avoiding the need to hold the station accurately for longer periods of time.

Probe Control and Deployment

vCompact uses motorised mechanisms which enable the probe to accurately follow the area to be inspected. Inspection data is transferred using ethernet to topside computer and can be available for immediate analysis and reporting.

Full coverage of the area to be inspected is achieved by adjustments to the probe in both parallel and transverse directions.

vCompact Features and Benefits

- Robust, compact design aids ease of handling on deck and integration with ROV.

- Versatile design for axial and circumferential measurements.

- A unique ‘teach and learn’ system ensures high-quality, repeatable inspections.

- Designed for deployment on a range of diameters.

- Magnetic or clamp versions for ferrous and non-ferrous materials.

- Multiple NDT technology options, including ART, SPA™, ToFD, SPECTA™ and ACFM® .

- Provides direct quantitative wall thickness measurement with highly accurate depth sizing (± 0.2mm).

- The low-profile design lends itself to tight access applications.

- Instant data capture for audit and comparison.

NDT Technology Options

What technologies are best suited to your subsea inspection application?

Case Studies

Through Coating Wall Thickness Inspection for ILI Verification

Beach Energy Ltd contracted TSC Subsea to carry out a wall thickness inspection through coating on the 20 in pipeline. The inspection was to determine the size and depth of corrosion which had been identified during a previous In-Line Inspection (ILI).

Inspecting Concrete Weighed Pipes with SPECTA

TSC Subsea was contracted by a client to carry out wall thickness assessment of Condensate Export Pipeline (CEP) and Pipeline End Manifold (PLEM) without removing the protective concrete weight coat (CWC).

4” of Coating no Match for ART and ARTEMIS

The purpose of the inspection was to measure effective steel thickness through 4 inches of pipeline insulations made of Glass syntactic polypropylene and injection moulded polypropylene. Scanning operations were carried out at 2000 meters water depth.

See all case studies