ART vPush

ART vPush provides a fast and efficient solution for hydrate detection and sizing

ART vPush

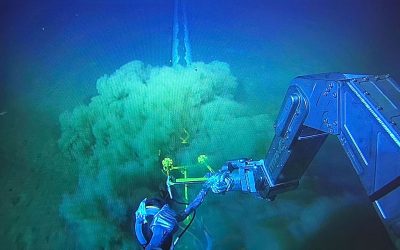

The ART vPush tool utilises TSC Subsea’s proprietary ART technology on a moving platform to rapidly assess pipeline contents over complete pipe runs. Data is collected in real time and processed with several automated algorithms to monitor signals from the far wall of the pipeline. Based on the signal TSC Subsea is able to determine what the contents are – liquid, gas or hydrates

Four ART transducers work simultaneously to provide good coverage of the internal volume without requiring excessive dredging. Sensors located between 10 and 2 O’clock process signals from the far wall, providing 360 coverage without having to access the underside of the pipe. Data is encoded with an on-board odometer, linking data to its position on the pipe.

The tool is a welded stainless-steel frame designed to protect transducers from knocks and maintain their alignment with the surface of the pipe. The ROV pushes the tool via a compliant handle, allowing vertical play, but maintaining circumferential alignment. The handle and level of compliance can be customized for the ROV manipulator as required. Brushes can be fitted to the underside ahead of transducer paths aiding removal of loose debris. There are also additional mounting points for extra handles, cameras and/or water jetters (for the removal of loose sediment from the pipe).

Deployment

The pipe for inspection should have the top half exposed and clearance to the sides and above for the tool to passage along the pipe. Cleaning should be to a level that will not interfere with the alignment of the tool and pipe and not interfere with the ART signals.

The ART vPush is deployed via ROV manipulator or fitted directly to an ROV if required. Probes are pre-positioned on the tool and aligned to the surface using a sample pipe. Progress is monitored via ROV cameras, tooling cameras and odometer. Pipe-fitted sacrificial anodes can be negotiated by simply pausing the scan and lifting the tool over.

Key Features & Benefits of the ART vPush include

Minimal dredging requirements ensure reduced overall costs

Robust multi-sensor design provides accurate and repeatable data collection

Through-coating inspection

Circumferentially and axial staggered transducers for maximum coverage and minimal signal-interference/interaction

Odometer for location-encoding of data

Custom algorithms for signal monitoring and pipe content verification

Stiff frame to maintain transducer alignment

Wheeled free-running tool is simple and robust

Compliant handle to eliminate ‘wobble’ from ROV

Camera views of each transducer’s path

Additional mount points for handles / jetters etc

Our Services

Subsea Structures

Splash Zone

Vessels and FPSOs

Flexible Risers

Pipelines

Grouting

Case Studies

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Rapid Hydrate Plug Detection Solution for Subsea Pipelines.

Introduction In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for...

Smooth Sailing with ACFM Crack Assessment on Cargo Ship Propellers.

The Archon Gabriel Bulk Carrier was navigating the cold waters of the Gulf of Finland. The harsh sea conditions, laden with sea ice, posed significant navigational challenges and resulted in the ship’s 6-meter diameter bronze propeller suffering ice damage. Given the...

Diverless ACFM Inspection Solution for FPSO Bilge Keel Weld Integrity Assessment.

FPSO operators are increasingly seeking ways to inspect their hulls below the waterline without resorting to drydocking, a costly process that entails significant production loss, rendering it inefficient and logistically challenging. Recognising the benefits of a...

Solutions