ART vCaliper™

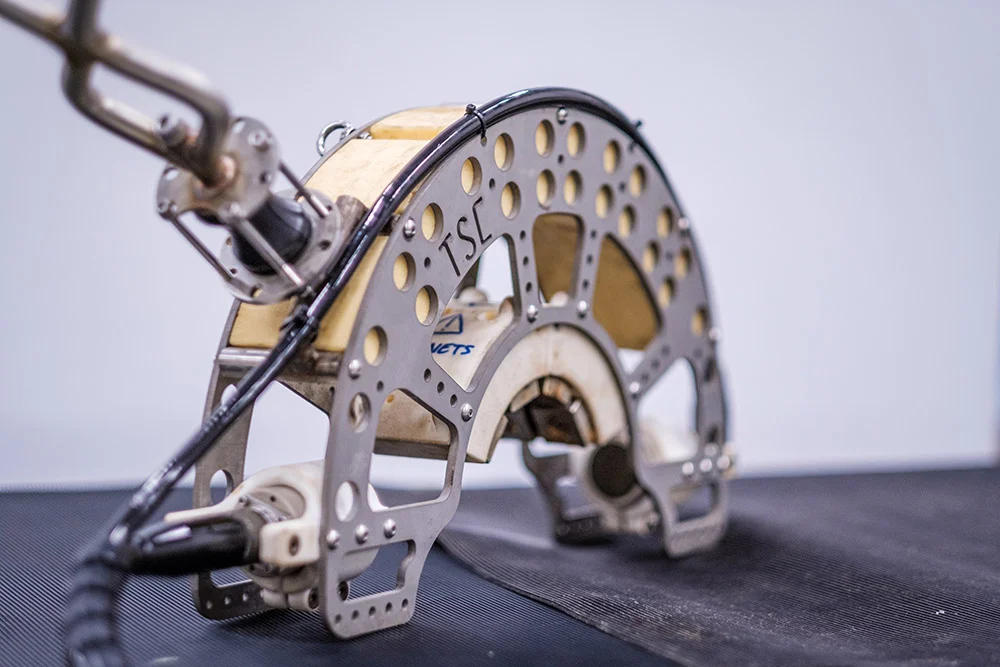

The ART vCaliper™ is a non-intrusive, lightweight, remotely-deployed advance inspection system especially used to obtain pipe ovality, dent measurement as well as high-resolution wall thickness measurements for areas with confined space or tight assess using TSC Subsea’s field proven Acoustic Resonance Technology (ART).

ART vCaliper™

The ART vCaliper™ was designed, developed and built by TSC Subsea’s team of engineers as a bespoke tool to address challenges during a subsea tie back project. The requirement was to inspect the hot tapping location to check for potential ovality and metal loss issues which had limited access for the tool.

The ART vCaliper™ has since proven to be effective for a wide array of uses, particularly when accurate measurements are needed for critical subsea structures with tight access. Common applications include pipeline hot tapping, dent measurement, and sizing for repair clamps, pipelines and other tubular structures, and jackets.

ART’s ability to provide high accuracy pipe ovality measurements as well as high resolution wall thickness through almost any thick subsea coating, results in major cost savings by eliminating the time and effort that would be required for coating removal.

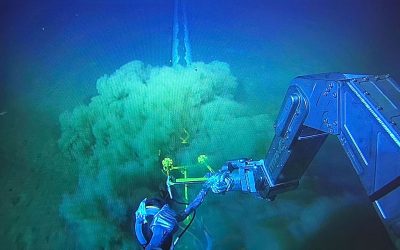

Deployment

ART vCaliper™ Features and Benefits

Remotely-deployed system with easy interface to all common ROVs, eliminating personnel risk

Light weight and robust design to access tight areas

Provides accurate ovality measurements for dent assessment or repair as well as direct quantitative wall thickness measurements with highly accurate depth sizing (± 0.2mm)

Unique design requires limited dredging around the pipe for access and full coverage

Performs a full circumferential scan efficiently by just moving the tool 180o

High tolerant to soft marine growth and requires limited surface preparation such as HP jetting and brushing

Flexible design enables inspection from 6”-20” and above, with minimal adjustment via a single tool

Capable of deep-water inspection to a depth of 3000m or 300bars

Our Services

Subsea Structures

Splash Zone

Vessels and FPSOs

Flexible Risers

Pipelines

Grouting

Case Studies

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Rapid Hydrate Plug Detection Solution for Subsea Pipelines.

Introduction In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for...

Smooth Sailing with ACFM Crack Assessment on Cargo Ship Propellers.

The Archon Gabriel Bulk Carrier was navigating the cold waters of the Gulf of Finland. The harsh sea conditions, laden with sea ice, posed significant navigational challenges and resulted in the ship’s 6-meter diameter bronze propeller suffering ice damage. Given the...

Diverless ACFM Inspection Solution for FPSO Bilge Keel Weld Integrity Assessment.

FPSO operators are increasingly seeking ways to inspect their hulls below the waterline without resorting to drydocking, a costly process that entails significant production loss, rendering it inefficient and logistically challenging. Recognising the benefits of a...

Solutions