Through our exclusive underwater Non-Destructive Testing (NDT) technologies and remote robotic scanners, we empower our customers to perform integrity assessments on their subsea assets including pipelines, flexible/rigid risers, offshore structures and vessels while minimising costs, reducing environmental impact, and enhancing personnel safety.

Subsea NDT Applications

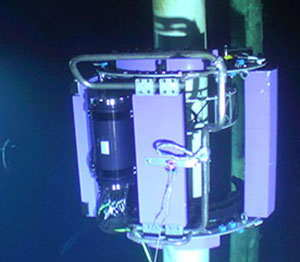

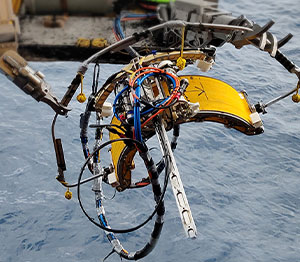

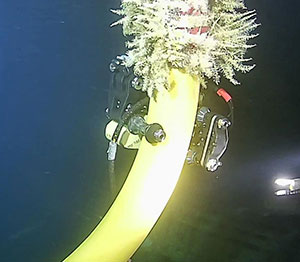

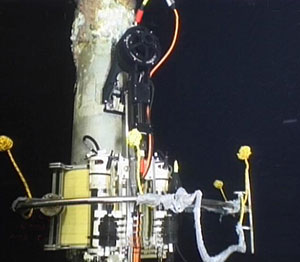

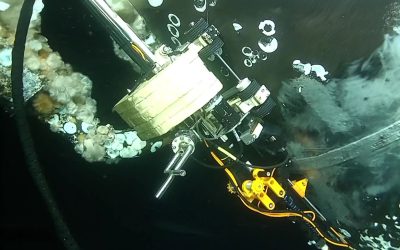

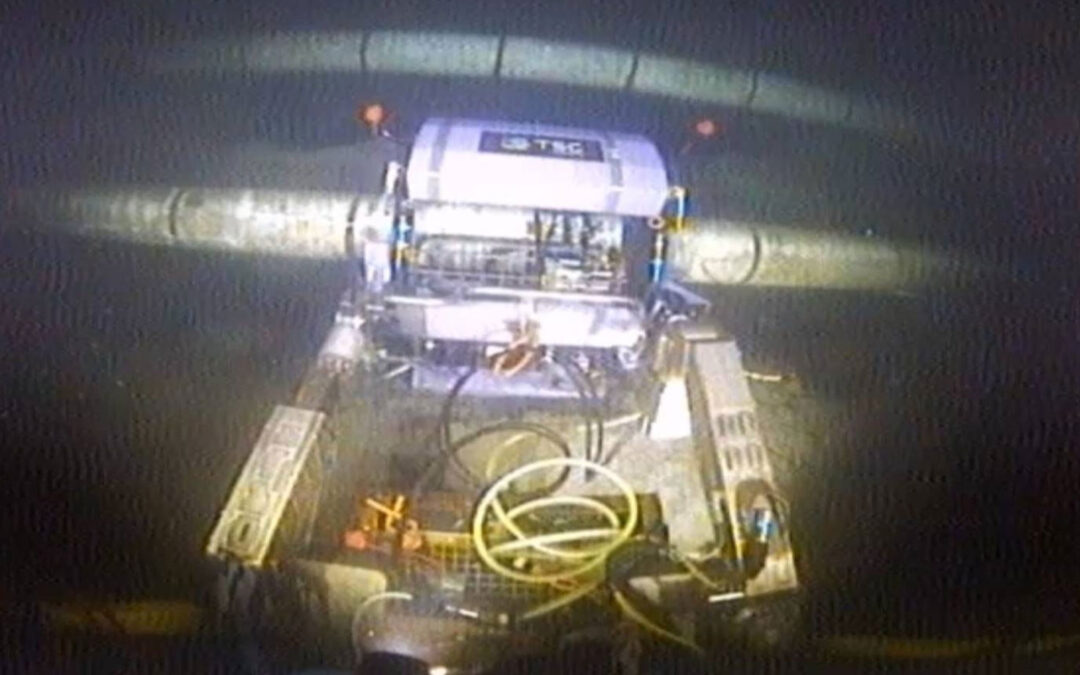

TSC Subsea distinguishes itself by providing a wide array of NDT techniques and subsea robotic inspection systems deployable via remotely operated vehicles (ROVs) or divers. This versatility enables us to carefully choose and utilise the most suitable NDT methods that align with the unique needs of our customers.

We are committed to delivering superior quality and reliable inspection data on time, every time. We assure our customers of accurate subsea asset integrity assessments, enabling them to make well-informed decisions and instilling confidence in their operations.

“With TSC Subsea we found a reliable partner with whom we were able to complete the relevant offshore work in a safe manner, within the scheduled time frame and within the planned budget.”

Ocean Breeze Energy GmbH (OBE) Project Manager

Subsea Inspection Services

With a track record of over ten years in resolving subsea inspection challenges across various water depths, ranging from the splash zone to ultra-deepwater, we possess the knowledge and experience in assessing the following types of damage mechanisms and typical issues associated with vital underwater assets:

- Validation of In-Line Inspection (ILI) surveys.

- Evaluation of internal pipeline corrosion and erosion.

- Detection and measurement of weld defects.

- Inspection of welds in subsea structures.

- Corrosion Under Insulation (CUI) assessment.

- Measurement of pipeline geometry, including ovality and dents.

- Subsea corrosion mapping.

“Each local area data collection was completed 5 times quicker compared with the Computed Tomography (CT) tool used in Gulf of Mexico (GoM) which was the only external local inspection technology available for deepwater production systems at that time.”

Shell Project Manager

Advanced NDT for Subsea

Our comprehensive portfolio encompasses a range of NDT inspection technologies. These advanced techniques seamlessly integrate with a variety of subsea robotic scanners, all of which can be deployed via remotely operated vehicles (ROVs) or divers.

What technologies are best suited to your subsea inspection application?

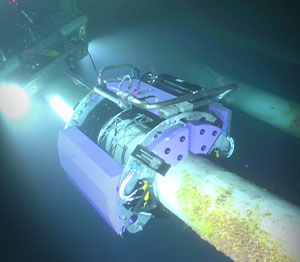

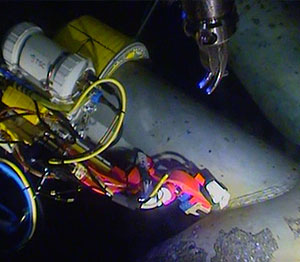

Underwater Robotic Deployment

TSC Subsea’s remote inspection robotics allows our clients to efficiently and cost-effectively monitor their subsea assets and infrastructure. Our field-proven robotic delivery systems ensure high-quality NDT inspection data, enabling clients to make informed operational decisions based on reliable and repeatable inspection results. This approach minimises unscheduled stoppages, incidents, and environmental leaks, ensuring smoother and more sustainable operations.

Case Studies

ARTEMIS: Through-Coating Inspection for Large-Diameter Subsea Pipelines.

A primary objective was to assess areas expected to become dead legs as a result of future pipework rearrangements. These dead legs, along with the commingling point for flow back to Nyhamna, have been assessed as susceptible to Flow-Assisted Corrosion (FAC),...

ARTEMIS: Through-Coating Inspection for Large-Diameter Subsea Pipelines.

A primary objective was to assess areas expected to become dead legs as a result of future pipework rearrangements. These dead legs, along with the commingling point for flow back to Nyhamna, have been assessed as susceptible to Flow-Assisted Corrosion (FAC),...

vCompact™ in Action: Corrosion Mapping & Weld Integrity Assessment of Subsea Pipelines.

A leading offshore operator in the South China Sea relies on a network of subsea pipelines and flowlines to transport oil and gas from wells to its production facilities. Over the years, these pipelines have been at risk of saltwater corrosion, mechanical stress, and...

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

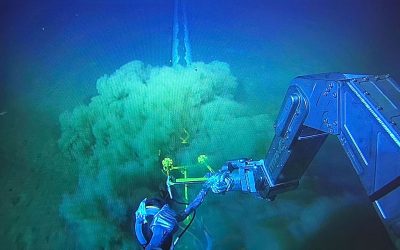

Rapid Hydrate Plug Detection Solution for Subsea Pipelines.

Introduction In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for...

Get in touch

Want more information about TSC Subsea’s unique, cost-effective solutions? Just fill out the form with your questions or information requests, and we’ll promptly get in touch with you.

Latest News

NodeScanner™: 10 Years of Protecting Offshore Structures

Introduced in 2016, NodeScanner was built on more than three decades of subsea Alternating Current Field Measurement (ACFM) expertise. The system brought proven crack detection and quantitative sizing capability into a purpose-designed, ROV-deployed inspection...

TSC Subsea & Remotion Collaboration Shortlisted for Petrobras Robotic FPSO Hull Inspection Challenge

Petrobras challenged the global industry to develop a robotic solution that could clean and conduct corrosion mapping of the hull and be launched directly from the FPSO deck, eliminating the need for divers, ROVs, or additional support vessels. The system needed to be...

Contract Award: Subsea Circumferential Weld Inspection in Ultra-Deepwater Offshore Brazil.

Phased Array Ultrasonics (PAUT) is widely recognised for its effectiveness in topside weld inspection and its accuracy in detecting and sizing cracks and defects. TSC Subsea has now adapted this proven technique for ultra-deepwater environments, helping ensure the...