VISTATM

Diver Deployed Muti-technology Underwater NDT Scanner

VISTA (Versatile Inspection System for Subsea Technical Assessment) is a multifunctional hybrid diver deployed scanner, combining advanced Alternating Current Field Measurement (ACFM®) and Subsea Phased Array (SPA™) technologies for corrosion mapping and weld integrity assessment. This scanner will provide quantitative data sets for remaining wall thickness and full volumetric inspection of welds and other structures.

TSC Subsea’s inspection services offer a comprehensive range of diver-deployed inspection solutions utilising advanced non-destructive testing (NDT) methods such as:

Our latest innovation, VISTA, is a multifunctional, multi-technology hybrid scanner designed to assist divers in conducting underwater inspections. It combines advanced ACFM and SPA technologies for corrosion mapping and weld inspection. This scanner will provide quantitative data sets for remaining wall thickness and full volumetric inspection of welds and other structures.

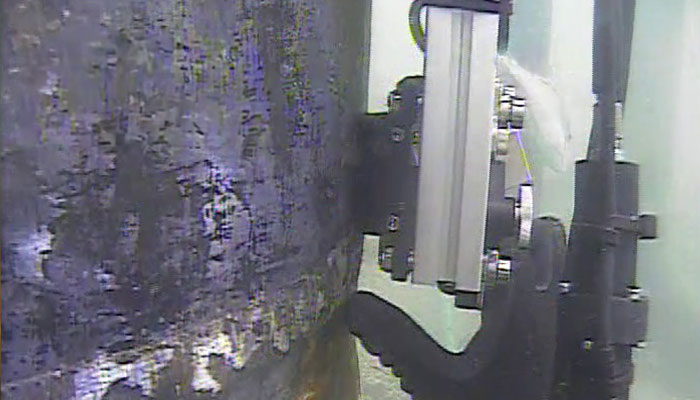

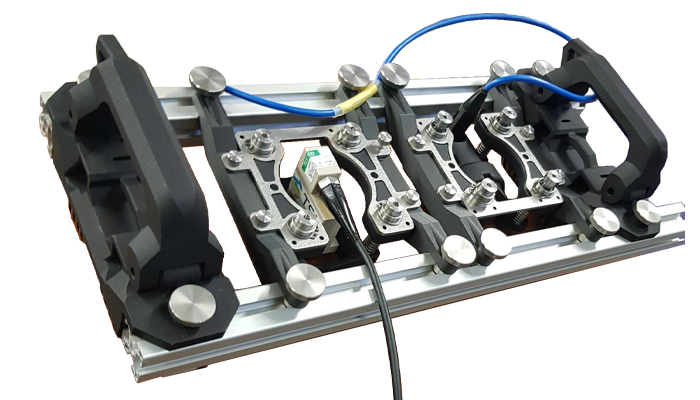

The lightweight, low-profile scanner, equipped with magnetic wheels and easily switchable brakes, reduces the diver’s burden while ensuring excellent data quality and increasing inspection efficiency.

The dual-bar arrangement provides industry-leading probe stability, superior scan accuracy, and manoeuvrability, ensuring more reliable inspections while reducing the time a diver spends underwater.

Underwater Applications

- Circumferential and longitudinal welds inspection

- Crack detection, sizing & monitoring

- Corrosion/erosion detection & sizing

- Vessel circumferential welds

- Pipe to elbow/feature welds

- Subsea storage tanks

- Flange face inspection

VISTA Features

- Perform circumferential and longitudinal inspections on subsea assets from 30 mm (1.2 in) diameter to flat plate.

- Powered by Eddyfi Gekko & Amigo2.

- Lightweight and low-profile design, perfect for tight spaces.

- A dual-bar setup provides probe stability and superior scan accuracy.

- Magnetic wheels ensure adherence to the inspection surface.

- Accommodate up to 2 SPA or TOFD probes.

- Easily apply brakes to prevent slippage when not scanning.

NDT Technologies

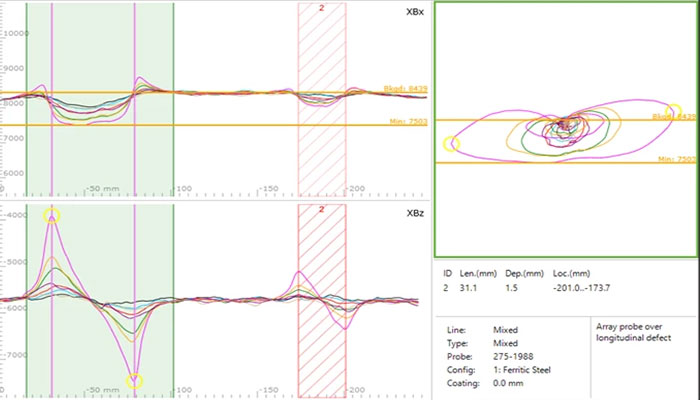

- High-resolution corrosion mapping and volumetric weld assessment.

- Advanced techniques, including ToFD and TFM.

- Improved defect detection with a high probability of detection from a single probe position.

- Suitable for ferrous and non-ferrous assets.

- Surface-breaking crack detection and sizing.

- Recognised and approved by many certification bodies, including DNV, ABS, BV and Lloyds.

- Computerised auditable data, unlike MPI.

- Reliable results despite surface imperfections.

Get in touch

Downloads

Case Studies

External Subsea Inspection of Flexible Risers

Flooded annulus due to an external sheath breach has proven to be one of the top failure modes of flexible riser systems. It has also been found that CO2 permeation from produced fluids can accelerate armor wire corrosion, leading to flexible riser failure.

4” of Coating no Match for ART and ARTEMIS

The purpose of the inspection was to measure effective steel thickness through 4 inches of pipeline insulations made of Glass syntactic polypropylene and injection moulded polypropylene. Scanning operations were carried out at 2000 meters water depth.

Subsea Pipelines Dent Mapping and Ovality Assessment

TSC Subsea received a request to conduct a wall thickness measurement inspection and ovality/dent assessments on a 16-inch (406 mm) subsea gas pipeline, accompanied by a 2-inch (50 mm) piggyback pipeline.

See all case studies