Introduction

In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for subsea operators. These icy formations can accumulate along the inner surface of the pipeline, severely impeding or even completely obstructing flow, leading to costly remediation efforts.

While detecting a reduction in flow is straightforward, pinpointing the exact location of a blockage within a pipeline is a daunting task. Addressing hydrate blockages effectively requires understanding the plug’s characteristics, location, and the extent of the obstruction.

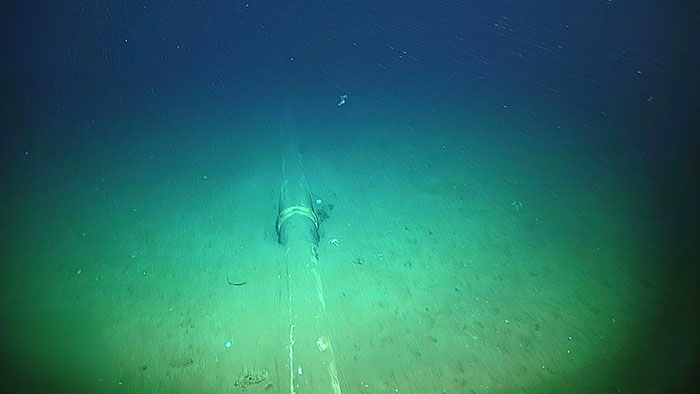

The challenge was especially tough in this case: a 9 km flowline at a depth of 1700 meters (5577 feet), with a 323 mm (12 in) outside diameter and a 19 mm (0.75 in) wall thickness, encased in a 3.5 mm (0.14 inch) Three Layer Polyethylene/Polypropylene (3LPE) coating.

Solution

Enter TSC Subsea with their award-winning vPush scanner, equipped with proprietary Acoustic Resonance Technology (ART).

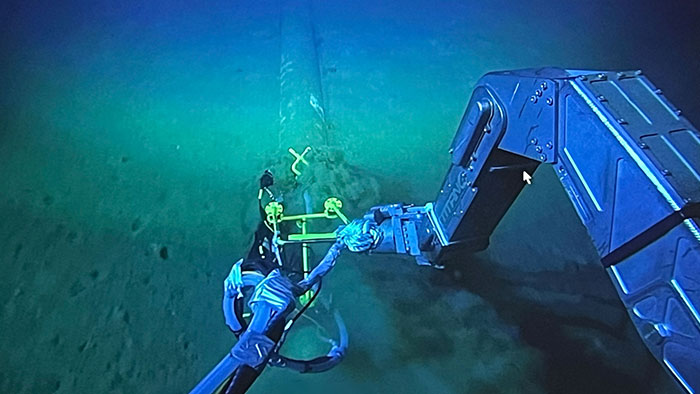

Deployed via remotely operated vehicles (ROV), the vPush is pushed along the upper surface of the subsea flowline, collecting data in real-time from its four sensors. This approach allows for the rapid detection of hydrates as quickly as the ROV can travel the pipeline’s span.

A Standout features of the ART vPush is its ability to penetrate through the coating, eliminating the need to remove and replace. Also, the minimal dredging requirement, as it only needs access to the top half of the pipe.

The vPush is also equipped with brushes and a water jet to clear any sediment from the pipe surface.

The vPush’s four transducers worked simultaneously, providing full coverage of the internal volume.

Sensors positioned between 10 and 2 o’clock examined signals from the far wall, as well as comparing acoustic signatures from the pipe wall, which change when Hydrate is present. The system provides 360-degree coverage without accessing the underside of the pipe.

Whilst scanning, the ART technicians were on the vessel’s topside, analysing the data in real time, and providing feedback to the client.

Result

The campaign was a resounding success. Two hydrate formations were detected, one measuring 10.1 m (33 ft) and the other 8.8 m (29 ft). The operator not only identified the exact locations and sizes of the hydrates but also achieved significant cost savings:

Minimal Dredging: Thanks to the smart design of the ART vPush, only minimal dredging of the upper section of the pipe was needed.

Reduced ROV and Vessel Time: High-speed data collection minimised the time required for ROV and vessel deployment, further cutting costs.

Conclusion

The deployment of TSC Subsea’s vPush scanner, with its advanced Acoustic Resonance Technology, provided an effective and efficient solution to the hydrate blockage issue in the subsea flowline. This unique technology ensured accurate detection and measurement of hydrate formations while offering significant cost savings.

By providing the operator with the exact location and length of the two discovered hydrates, they were able to commence remediation action.

This case study underscores the critical role of advanced technological solutions in addressing complex subsea challenges, ensuring operational efficiency and cost-effectiveness for offshore operators.