TRITON

Bi-directional Tethered In-line Inspection (ILI) Robotic Crawler for Unpiggable Pipelines

TSC Subsea’s TRITON bi-directional robotic crawler is a tethered In-line Inspection (ILI) solution that redefines internal pipeline integrity assessments for unpiggable, non-piggable, and challenging-to-inspect pipelines.

Offering both targeted and continuous inspection modes, TRITON delivers maximum flexibility. In continuous inspection mode with Acoustic Resonance Technology (ART), operators benefit from minimal or no cleaning requirements, quantitative wall loss data, and field-proven power to overcome complex pipe configurations.

Tethered Robotic Crawler for Unpiggable Pipelines

Ensuring the integrity of pipeline systems is crucial for optimising efficiency and production rates while minimising environmental impact and ensuring the safety of personnel and the public. Neglecting pipeline maintenance can result in decreased production and, in the worst-case scenario, lead to catastrophic failures due to unidentified cracks or corrosion.

Pipeline operators commonly opt for in-line inspection (ILI) pigging solutions, but these methods require specific pig launching and receiving facilities. When such facilities are unavailable, the pipeline is typically labelled as an unpiggable pipeline. This is where Triton comes into its element.

Unpiggable Pipeline Inspection Modes

Continuous Inspection

- Function: 360° scan coverage while in motion

- Detection: Wall thickness, metal loss (internal/external), laminations, ovality, coating degradation

- Technology: Acoustic Resonance Technology (ART)

- Requirements: Depressurised, liquid-filled lines with open access

Targeted Inspection

- Function: Drive, stop, and scan

- Detection: Weld inspection, crack detection, corrosion mapping, laser scanning, remote visual inspection

- Technologies: PAUT, ACFM, ART, PEC, RVI

- Requirements: Depressurised, liquid-filled or dry lines with open access

Why Choose TSC Subsea & TRITON

Proven Success on Unpiggable Pipelines

TRITON has repeatedly delivered reliable inspection results in pipelines considered unpiggable, including risers with no launch facilities, over distances of 1.5 km or more.

Multi-Technology, Customisable Platform

Integrates a range of NDT methods (ART, PAUT, ACFM, PEC, Laser, RVI) to meet exact inspection needs, from continuous wall loss to targeted crack detection in a single robotic solution.

Best-in-Class ILI Module – Backed by NDT Global

TRITON delivers continuous 360° wall thickness scanning using proprietary ART, maintaining high-resolution data capture even through light debris and sludge.

Pipeline Applications

- Unpiggable pipelines, subsea, offshore, or onshore

- Loading and offloading pipelines

- Crude oil lines

- Offshore risers

- Pipelines with internal obstacles or additional pipes, such as heat-tracing lines

- Short refinery pipelines leading to subsea installations

- Flowlines

- Low-flow / low-pressure pipelines

Pipeline Inspection Capabilities

- Ideal for systems with only a single access point (entry and exit at the same location)

- Navigates horizontal, vertical sections and bends with ease

- Modular design adapts to various pipe configurations

- Pipe diameters ranging from 8 in (200 mm) to 42 in (1066 mm)

- Operates at depths up to 150 m (492 ft) in flooded environments

- Standard inspection range of up to 1500 m (4921 ft)

- End-to-end 360° circumferential scanning or targeted localised inspection

- Suitable for use in both dry and submerged conditions

Modular Components

TRITON Robotic Crawler

TRITON integrates triple independently powered expandable tracks with an adaptable tripod chassis, enabling inspections across a wide range of pipe sizes and orientations.

Power and data are delivered through an umbilical system, providing real-time inspection data directly to the operator.

Engineered for versatility, TRITON navigates horizontal and vertical sections, multiple 90-degree bends, and operates in dry or wet environments. Its rugged anodized aluminium and stainless-steel construction ensures durability, while powerful LED lighting and high-resolution cameras provide clear visual assessments in harsh conditions.

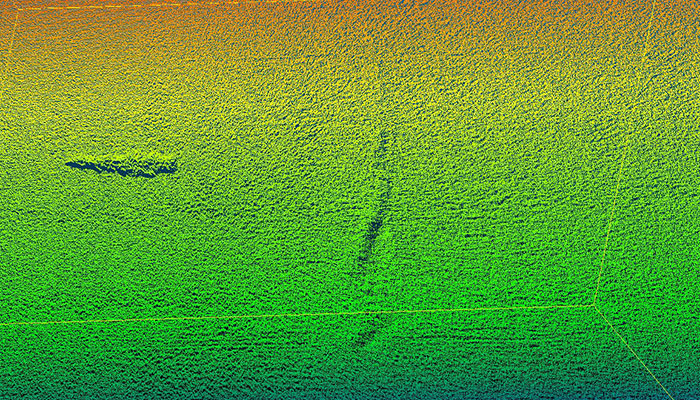

Continuous Inspection Module ART Scan ILI

The field-proven Acoustic Resonance Technology (ART) ultrasonic module offers the same advantages as traditional in-line inspection (ILI), providing continuous, sub-millimetre wall thickness measurements in liquid pipelines, including challenging areas like bends and heat-affected zones.

Unlike other NDT technologies, ART probes are non-contact, requiring minimal cleaning and demonstrating greater tolerance to varying surface conditions, internal debris, and sludge.

Targeted Inspection Module

The compact robotic scanner, equipped with interchangeable probe mounting modules, supports a variety of NDT technologies, including ACFM, PAUT, ToFD, PEC and laser scanning. Designed for versatility, the TRITON crawler pushes or pulls the module to the area of interest.

Once in position, it can perform a full 360-degree rotation independently, making it an ideal solution for weld integrity assessments and targeted high resolution corrosion mapping.

Advanced NDT Techniques

The adaptable Triton ILI internal pipe crawler can operate in both dry and wet environments. It can integrate various NDT techniques based on the inspection requirement, including corrosion mapping, wall thickness measurements, ovality and dents assessment, crack detection and sizing in welds, remote visual inspection and through coating or unprepared heavily corroded surfaces inspections.

- Alternating Current Field Measurement (ACFM®) for detecting surface-breaking cracks and sizing welds.

- Phased Array Ultrasonics (PAUT) for high-resolution quantitative wall thickness measurements, corrosion mapping, and volumetric weld inspection.

- Acoustic Resonance Technology (ART) for quantitative wall thickness measurements, through coating and unprepared surfaces.

- Pulsed Eddy Current (PEC) for inspecting highly corroded and scab surfaces.

- Remote Visual Inspection (RVI) with a high-resolution PTZ camera.

- Laser Scanning for a comprehensive 360-degree internal assessment.

Videos

Case Studies

Tethered ILI Robotic Solution for Internal unpiggable Riser Inspection

bp approached TSC Subsea with a unique challenge: to conduct an internal inspection of an unused riser located on one of their North Sea offshore platforms. Due to an upcoming development project, bp aimed to commission the riser for service.

External Subsea Inspection of Flexible Risers

Flooded annulus due to an external sheath breach has proven to be one of the top failure modes of flexible riser systems. It has also been found that CO2 permeation from produced fluids can accelerate armor wire corrosion, leading to flexible riser failure.

Inspecting Concrete Weighed Pipes with SPECTA

TSC Subsea was contracted by a client to carry out wall thickness assessment of Condensate Export Pipeline (CEP) and Pipeline End Manifold (PLEM) without removing the protective concrete weight coat (CWC).

See all case studies