Grout Integrity Inspection

Grout Assessments for Offshore Structures

Several offshore operators have structures with grouted connections, yet a technology gap exists to enable confirmation of grouting presence and integrity. Acoustic Resonance Technology, ART, offers a robust solution for grout integrity inspection and is capable of detecting typical failures in grouted connections in offshore structures.

Offshore Structure Grout Integrity Assessment

Grouted connections are used in several offshore structures including applications such as monopile and jacket foundations for oil rig platforms and windmill turbines. Damages may develop over time in these structures due to stress from cycling, like voids initiated in shear key areas and areas with different grout structures due to poor installation of the grout.

Reliable inspection of these structures is crucial in order to extend lifespan of the structures with grouted connections and ensure safety. In the past such inspections have been limited to visual inspection of the top area where the grout is visible and no information has been accessible from the grout behind the steel casings in the lower parts of such structures. In particular at the bottom of such structures, where the damage is believed to be most critical, a non-destructive inspection method is of high demand.

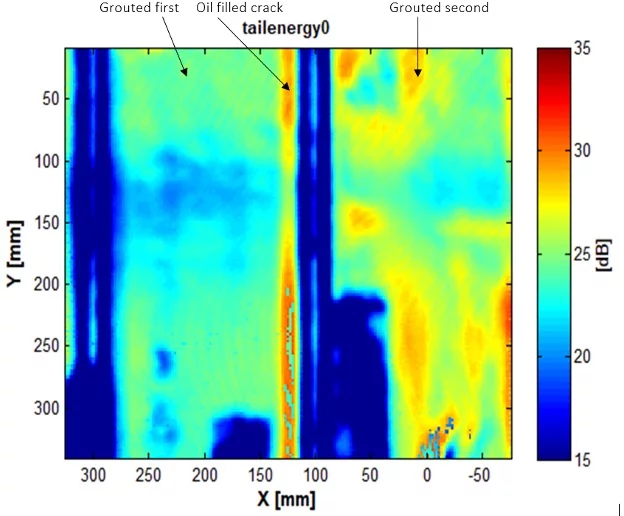

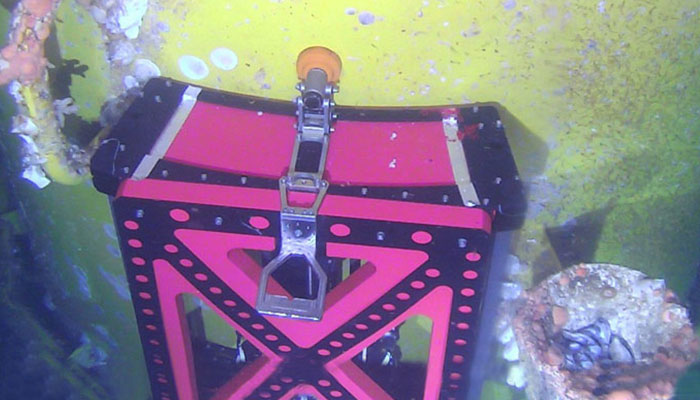

The TSC Subsea ART Guide is an ROV-mountable inspection tool developed for non-destructive external inspection of subsea assets with steel casings. It can be deployed to conduct inspections of grouted connections and provide in-depth analysis of the structure’s integrity by using several sensors, giving a high resolution image in real time.

The technology detects and maps defects such as:

• Dis-bondment between the steel and the grout

• Void behind the steel plate or detecting the presence of grout

• Cracks behind the steel plate

• Density change in the grout behind the steel plate

Some grouted connections are made with so called shear keys, to increase the resistance between the steel and the grout, and with the TSC ART Guide the position of the shear keys and the integrity of the surrounding grout can be detected.

Case Studies

Subsea Grout Integrity Assessment with ART

Grout integrity verification of subsea structures is now possible thanks to TSC Subsea’s innovative technology and the development of its unique solution, the ART GUIDE scanner. ART can verify the grouting integrity behind the pile sleeve and detect inconsistencies, such as voids, crushing and cracks in the grout.

Flooded Member Detection (FMD) with ART

The presence of water within a Caisson or any other subsea structure can serve as an indication of potential through-wall defects or cracked welds. Left undetected, these issues can significantly elevate the risk of structural failure. It is of utmost importance to conduct inspections to promptly identify and rectify these concerns.

Inspecting Concrete Weighed Pipes with SPECTA

TSC Subsea was contracted by a client to carry out wall thickness assessment of Condensate Export Pipeline (CEP) and Pipeline End Manifold (PLEM) without removing the protective concrete weight coat (CWC).

See all case studies