Subsea NDT Technologies

ART – Acoustic Resonance Technology

ACFM – Alternating Current Field Measurement

PEC – Pulsed Eddy Current

SPA – Subsea Phased Array

Our services

Subsea Structures

Splash Zone

Vessels and FPSOs

Flexible Risers

Pipelines

Grouting

Case Studies

ARTEMIS: Through-Coating Inspection for Large-Diameter Subsea Pipelines.

A primary objective was to assess areas expected to become dead legs as a result of future pipework rearrangements. These dead legs, along with the commingling point for flow back to Nyhamna, have been assessed as susceptible to Flow-Assisted Corrosion (FAC),...

ARTEMIS: Through-Coating Inspection for Large-Diameter Subsea Pipelines.

A primary objective was to assess areas expected to become dead legs as a result of future pipework rearrangements. These dead legs, along with the commingling point for flow back to Nyhamna, have been assessed as susceptible to Flow-Assisted Corrosion (FAC),...

vCompact™ in Action: Corrosion Mapping & Weld Integrity Assessment of Subsea Pipelines.

A leading offshore operator in the South China Sea relies on a network of subsea pipelines and flowlines to transport oil and gas from wells to its production facilities. Over the years, these pipelines have been at risk of saltwater corrosion, mechanical stress, and...

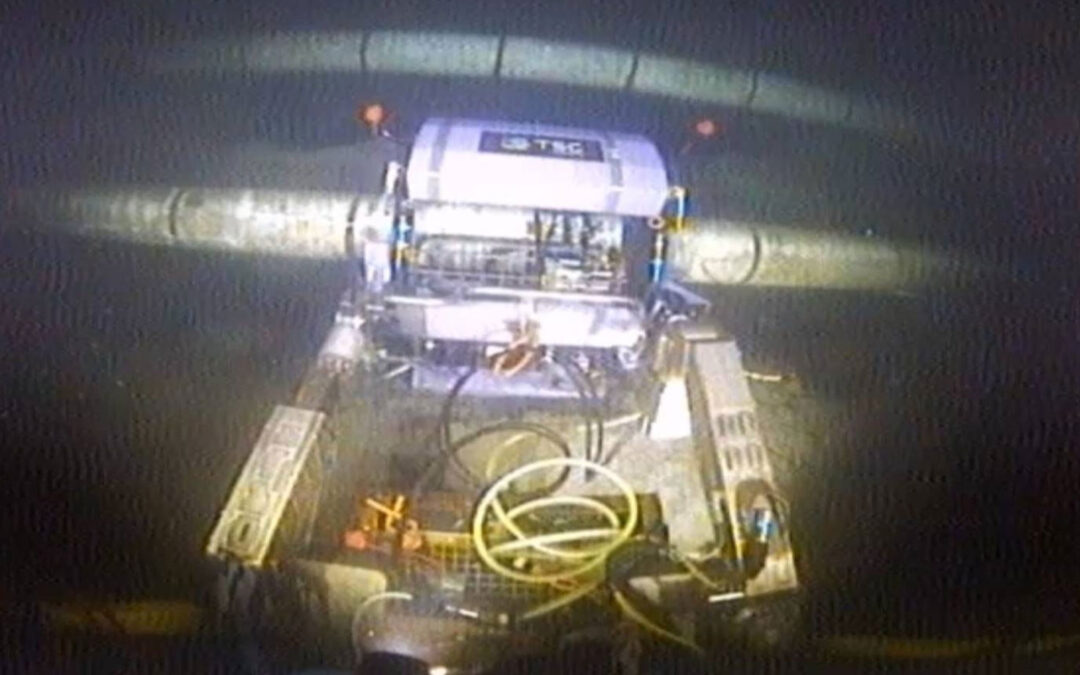

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

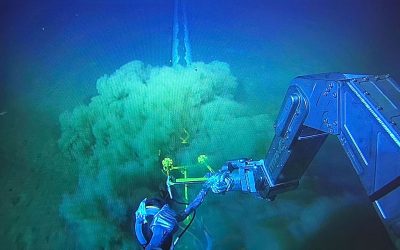

Rapid Hydrate Plug Detection Solution for Subsea Pipelines.

Introduction In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for...