Offshore Wind Structural NDT Inspection

Subsea Inspection Services

Inspecting offshore wind turbine’s underwater structural components is crucial for maximising the lifespan of these assets. Regular inspections are essential to prevent potential failures, which could lead to catastrophic consequences, including unplanned shutdowns and revenue loss.

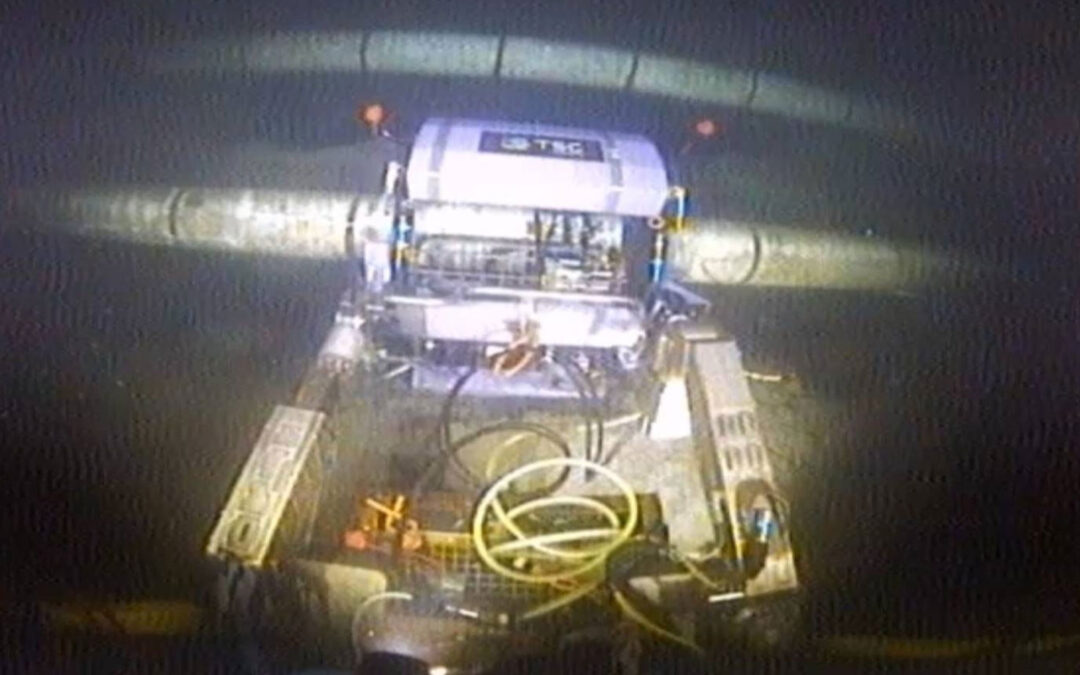

TSC Subsea’s advanced Non-Destructive Testing (NDT) techniques and remotely operated robotics systems have supported the offshore wind industry with grout integrity verifications, weld inspection, corrosion mapping and flooded member detection.

Historically, investment in technology and skills for offshore subsea inspection has primarily focused on the Oil and Gas industry. This has resulted in the existence of a considerable talent pool of highly skilled professionals and technology-driven service providers. The transition to offshore wind energy can leverage these skills and technologies to address the inspection requirements effectively.

Through close collaboration with global operators, TSC Subsea has developed and implemented cutting-edge proprietary technologies to tackle challenges in some of the world’s most demanding offshore worksites. With our expertise and advanced solutions, we are committed to supporting the energy transition to offshore wind by delivering efficient and reliable inspection services.

Grout Integrity/Displacement Measurements

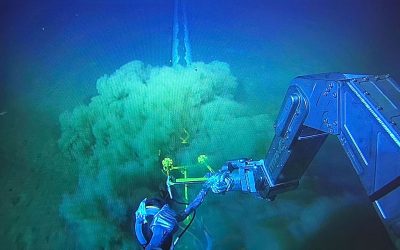

Grouted connections play a vital role in offshore structures, such as monopile and jacket foundations for platforms and wind turbine installations. However, over time, these structures may develop damages caused by cyclic stress, resulting in issues like voids in shear key areas or variations in grout structures due to inadequate grout installation.

The remotely deployed ART GUIDE™ system with Acoustic Resonance Technology (ART) is specifically suited for detecting the various failure modes found both in the steel and the grouted structure in the annulus.

- Dis-bondment between the steel and the grout.

- Voids, crushing and cracks in the grout.

- Density change in the grout behind the steel plate.

Structural Welds – Surface Cracking and Volumetric Inspection

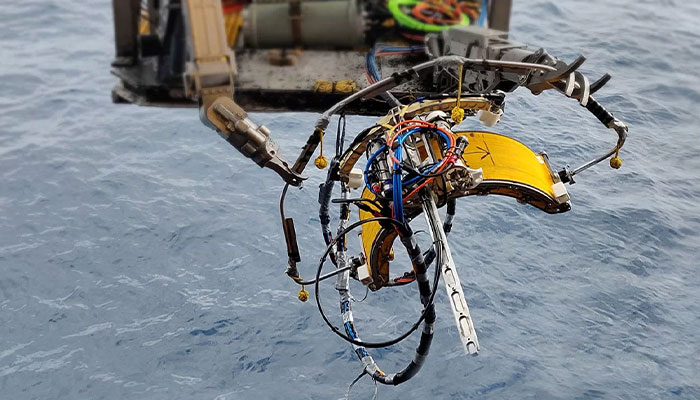

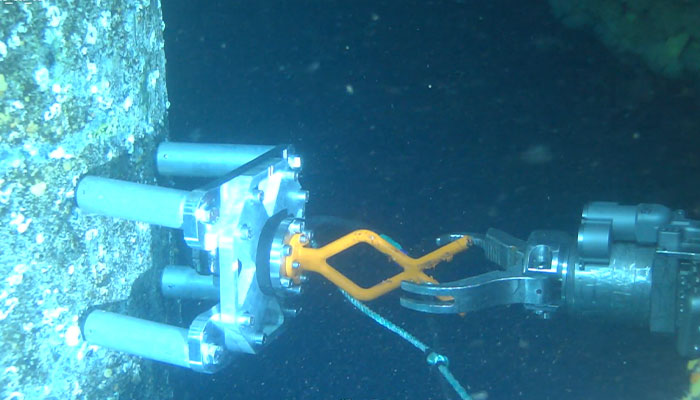

Regular inspections of structural nodal welds typically found on jacket style substations and turbines are crucial to identify cracks and defects that can result from significant dynamic loading. Due to the intricate nature of these welds, conducting inspections through direct scanning is not feasible. The challenging access associated with these areas often exceed the capabilities of divers.

The NodeScanner™ is designed to inspect tubular welded node joints and complex geometries. Equipped with Alternating Current Field Measurement (ACFM®) for detecting surface-breaking cracks and Subsea Phased Array (SPA™) for volumetric weld inspection.

- Surface breaking cracks.

- Lack of fusion or porosity.

- Slag and other inclusions.

Corrosion Mapping and Wall Thickness Measurement

The steel foundations or floaters of offshore wind turbines are susceptible to accelerated corrosion rates due to harsh environmental conditions, posing a significant challenge for wind farm owners. The increased corrosion risk raises concerns about potential structural failures and their catastrophic consequences.

We offer a comprehensive range of remotely deployable robotic scanners specifically designed for Subsea Phased Array (SPA™). By leveraging SPA technology, we enable precise and efficient corrosion assessment, providing numerous advantages for our clients.<

- Quantitive inspection data.

- Crack detection at varying depths and orientations.

- High-resolution wall thickness/corrosion mapping.

Advanced Flooded Member Detection (FMD)

The presence of water within a subsea structure can indicate potential through-wall defects or cracked welds, which, if undetected, can greatly increase the risk of failure. Conducting comprehensive inspections is vital to identify and address these issues in a timely manner, mitigating the risks associated with water ingress and flooded members.

Acoustic Resonance Technology (ART) is the perfect technology. Its ability to penetrate thick subsea coatings and materials gives it the power to defect unwanted mediums, such as water inside a structure from its external surface.

- Accurate and reliable readings through subsea coatings.

- Reduced cleaning times due to marine growth tolerance.

- Water level measurements.

NDT Technologies for Offshore Wind

Get in touch

Downloads

Case Studies

ARTEMIS: Through-Coating Inspection for Large-Diameter Subsea Pipelines.

A primary objective was to assess areas expected to become dead legs as a result of future pipework rearrangements. These dead legs, along with the commingling point for flow back to Nyhamna, have been assessed as susceptible to Flow-Assisted Corrosion (FAC),...

ARTEMIS: Through-Coating Inspection for Large-Diameter Subsea Pipelines.

A primary objective was to assess areas expected to become dead legs as a result of future pipework rearrangements. These dead legs, along with the commingling point for flow back to Nyhamna, have been assessed as susceptible to Flow-Assisted Corrosion (FAC),...

vCompact™ in Action: Corrosion Mapping & Weld Integrity Assessment of Subsea Pipelines.

A leading offshore operator in the South China Sea relies on a network of subsea pipelines and flowlines to transport oil and gas from wells to its production facilities. Over the years, these pipelines have been at risk of saltwater corrosion, mechanical stress, and...

Subsea Pipe Bend Inspection with ROV-Deployed Crawler and Phased Array Technology.

Introduction TSC Subsea was approached by a long-standing client, DeepOcean, acting on behalf of Repsol Norge AS, to conduct a diver-less, ROV-deployed inspection of multiple subsea pipe bends and T-sections of varying diameters. The inspection was to take place in...

Rapid Hydrate Plug Detection Solution for Subsea Pipelines.

Introduction In the deep waters off the coast of Angola, a major offshore operator faced a significant flow assurance issue with one of its 12-inch gas gathering flowlines. The suspected culprit? Hydrate plug. Hydrate formation is a major flow assurance concern for...