Flexible Riser Inspection

Riser Insight: Discovering the True Condition

The use of flexible piping has increased tremendously in the past decade. Its layered structure poses challenges for the inspection industry. If the outer sheath of the flexible pipe is breached, seawater can mix with the gases in the annulus, creating a corrosive atmosphere leading to failure. A reliable non-destructive inspection, which is able to penetrate the structural layers of the pipe, is therefore necessary. Acoustic Resonance Technology (ART) enables medium detection in the critical annulus area of the flexible pipe.

Flexible Riser Inspection

Since flexible risers have been in service, there has been a need and requirement to determine the medium within the annulus of the flexible pipe to understand the condition and to ensure it is fit for service.

Flexible pipe annulus medium detection is a challenge due to the complexity of the multi-layered and multimaterial structure in combination with the external forces caused by water depth.

Providing a reliable, non-intrusive inspection of the flexible pipe’s annulus has proven to be an industry challenge.

TSC Subsea solves this challenge using its proprietary Acoustic Resonance Technology (ART), a cost-effective, non-intrusive method to inspect flexible risers, pipelines and flowlines.

ART’s sensitivity and incredible penetration capabilities are very well suited to annulus medium detection solutions.

TSC Subsea has been developing deepwater subsea inspection application solutions for many years, including studies and testing focused on annulus medium detection.

The 3D model of an ART c-scan clearly identifies areas of the flexible annulus that contain an unwanted medium.

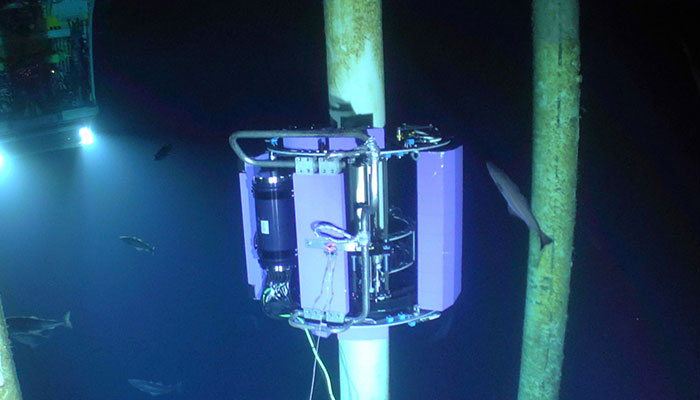

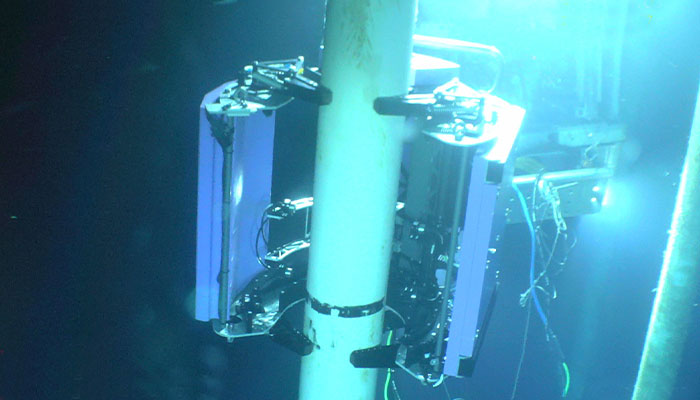

ARTEMIS® is TSC Subsea’s ROV-deployable inspection solution developed for external inspection of rigid and flexible pipelines, flowlines, and risers. It can be installed on most ROVs and easily deployed. The ARTEMIS® tool is able to penetrate layers of material and is adjustable for a range of pipe sizes.

ARTEMIS® solution:

- Characterises the medium within the annulus.

- Evaluate the outer sheath’s condition.

- Provides structural information for integrity analysis.

Case Studies

External Subsea Inspection of Flexible Risers

Flooded annulus due to an external sheath breach has proven to be one of the top failure modes of flexible riser systems. It has also been found that CO2 permeation from produced fluids can accelerate armor wire corrosion, leading to flexible riser failure.

4” of Coating no Match for ART and ARTEMIS

The purpose of the inspection was to measure effective steel thickness through 4 inches of pipeline insulations made of Glass syntactic polypropylene and injection moulded polypropylene. Scanning operations were carried out at 2000 meters water depth.

Wall Thickness & Ovality Assessments with ARTEMIS

With operating and development costs rising in the North Sea, companies are required to operate more cost-efficiently and utilise their assets effectively. With many platforms now extending production well beyond their original design life, increased maintenance is required.

See all case studies

Our services

Subsea Structures

Splash Zone

Vessels and FPSOs

Flexible Risers

Pipelines

Grouting

Solutions