The Challenge

TSC Subsea was initially contracted by C-Innovation to conduct weld inspections for a major operator in the GOM. Within its life extension plan, the operator is required to carry out crack detection of the column to pontoon welds as part of its UWILD inspection programme. The weld inspection was carried out using Alternating Current Field Measurement (ACFM®) technology via the ROV deployed MagCrawlerTM.

The ACFM® introduces an alternating current into the surface of a component to detect surface-breaking cracks. The presence of a crack disturbs the electromagnetic field and the return signal is instantaneously converted by advanced mathematical techniques so that operators are alerted to the presence of defects. Immediate defect sizing and recording is a major benefit compared to other NDT methods.

Prior to mobilisation, C Innovation asked if TSC Subsea could also conduct pipeline ovality and wall thickness checks on a potential hot tapping location on the gas buyback line of a semi-submersible platform as a combined scope. Access to the hot tapping inspection site was crowded with pipe work and clamps. This made it difficult to use standard scanners and also posed a danger to divers.

The Solution

The in-house team of engineers at TSC Subsea designed, developed and built a bespoke tool to carry out the hot tapping inspection work, the ART vCaliper. This non-intrusive, remotely deployed advanced inspection system uses TSC Subsea’s field proven Acoustic Resonance Technology (ART).

ART is a wideband ultrasound technique with its detection of resonating frequencies enabling a direct measurement of wall thickness to an accuracy of +/- 0.2 mm and ovality which met the exact requirements of C-Innovation.

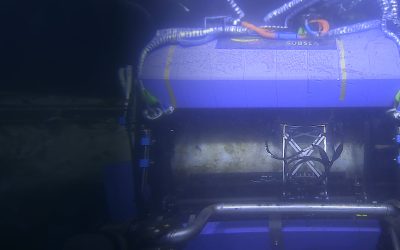

The engineering team based the design on aspects of TSC Subsea’s NodeScanner™, which uses magnets to fasten to the pipe and engineered the ART vCaliper specifically for this project. It was compact enough to fit into the constricted space and is easily manipulated by the ROV.

The turnaround time for developing the bespoke tool was less than four weeks from the initial request of C-Innovation.

The tool features two transducers 180°apart, which collect data simultaneously with a minimum collection of 3 readings for ovality.

The current design caters for inspection from 4-20” and can be engineered to any diameter required. It easily interfaces with all common ROVs, and is lightweight, using a magnetic motorless arc to fasten on to the pipe. It provides full 360° coverage around the pipe with simple manipulation by an ROV.

The Results

The ACFM® MagCrawler™ and ART vCaliper™ were deployed to perform crack detection, ovality and wall thickness measurement in a single inspection campaign. In addition, both ART and ACFM® are less impacted by the presence of marine growth which means limited surface preparation is required.

With the restrictions surrounding COVID-19 and the drive to reduce personnel on board (POB) during inspection, live data collection review and analysis was carried out remotely from TSC Subsea’s UK facility. The combination of these factors led to reduced vessel time and minimal POB, and safer operations by removing diver dependence. This ultimately resulted in reduced costs for the client.

The inspection was successfully carried out and determined that the pipe work at the site of the proposed hot tap was free from excessive corrosion and was sufficiently round for the hot tap procedure to go ahead. The results from the ACFM® crack detection confirmed no significant defects at the inspection points.